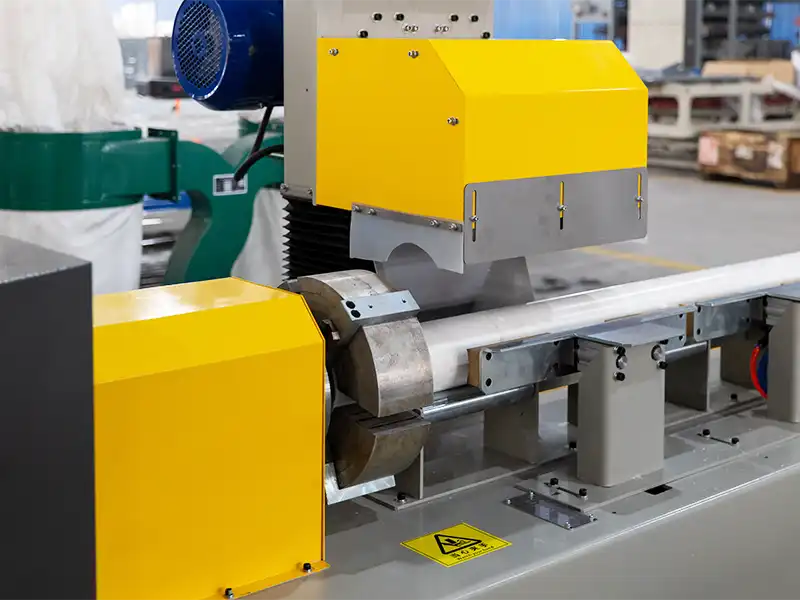

Pipe Slotting Machine Manufacturer

- Our pipe slotting machine ensures high-speed cutting, consistent slot dimensions, clean finishes, reduced waste, and improved product performance and reliability.

- Engineered for seamless integration into your existing pipe extrusion line, it ensures synchronized operation with your extruder for continuous, efficient production.

- Suitable for pipe diameter 75mm-250mm

- Suitable for pipe thickness 3-10mm

- Vertical and horizontal type

- Modular configuration

Work Principle of Pipe Slotting Machine

- Pipes are fed into the slotting machine automatically or manually using rollers.

- Adjustable clamps securely hold the pipe to prevent movement during slotting operation.

- High-speed circular saws or milling tools cut precise slots on pipe surfaces.

- Slot depth and spacing controlled by PLC or mechanical adjustment for precision.

- Pipe rotation or blade movement depends on the machine’s specific design.

- Cooling prevents overheating; vacuum or blower systems remove dust and plastic chips.

- Integrated with extrusion lines, slotting speed syncs with extrusion for continuous production.

- Slotted pipes exit the machine and are collected for processing or packaging.

What Pipe Material Can We Slot?

- Our pipe slotting machine supports PVC, PP, and PE pipes with various thicknesses, offering clean, precise slots across different material properties.

PVC

- 80-85 Hardness

- Thermal resistance up to 60-70°C

- Typical 2.0-8.0 mm wall thickness

PP

- 70-75 Hardness

- Thermal resistance up to 100°C

- Typical 2.5-6.0 mm wall thickness

PE

- 55-70 Hardness

- Thermal resistance up to 80°C

- Typical 1.5-6.0 mm wall thickness

What Slotting Type Can We Cut?

- Our pipe slotting machine offers vertical and horizontal types for precise axial or perpendicular cuts on plastic pipes.

Vertical Type

Horizontal Type

What Textures of Pipe Can We Slot?

- Our pipe slotting machine can slot not only smooth pipes but also corrugated pipes with precision and efficiency.

- Designed to accommodate the irregular outer surface of corrugated pipes without damaging the pipe structure.

- Slotting blades are precisely aligned to cut on the crest (outer wave) of corrugated surfaces, ensuring consistent groove depth.

Get an Instant Quote and Production Plan

Achieve perfect slots while reducing waste and downtime.

What Can Our Equipment Customize for You?

Pipe Diameter Range

- Configure for small, medium, or large plastic pipes (75mm-250mm)

Slot Dimensions

- Adjustable slot length width, depth, and spacing based on application needs

Number of Slotting Blades

- Single or multi-blade setups for faster or more complex patterns

Feeding System

- Manual, roller feed, or fully automated conveyor integration

Dust cover

- Equipped with dust cover to prevent overflow and protect cleanliness.

Any Query? Let Us Know.

Frequently Asked Questions

Can your slotting machine integrate with an extrusion line?

Absolutely. Our slotting machines can be seamlessly integrated into plastic pipe extrusion lines for inline operation.

Is the slotting speed adjustable?

Yes, the slotting speed can be adjusted via the control panel to match different pipe materials and production speeds.

Do you provide training or installation support?

Yes. We offer on-site installation, operator training, and online technical support to ensure smooth commissioning and operation.

What maintenance is required?

Regular blade checks, part lubrication, and dust system cleaning ensure reliable long-term machine performance.