Belling Machine Manufacturer

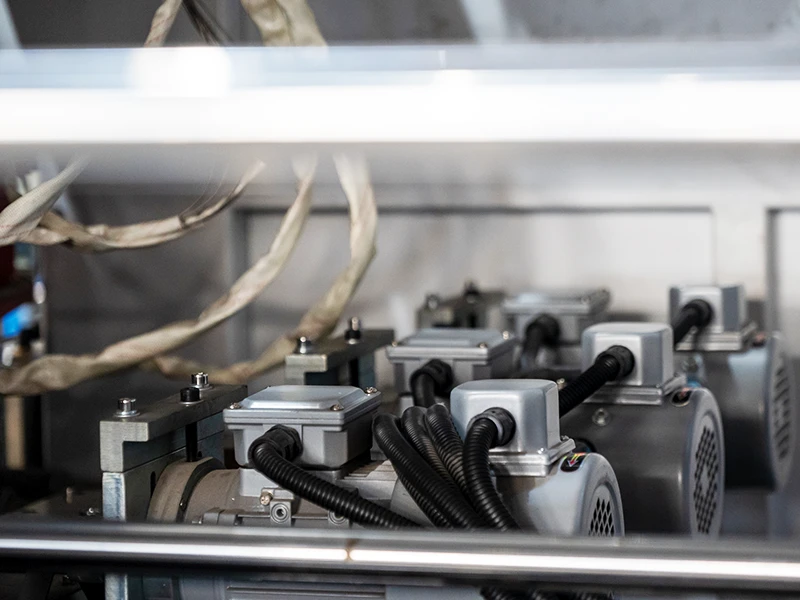

- We provide high-performance belling machines for plastic pipes, ensuring precise socket forming, consistent quality, and seamless integration with extruders.

- With advanced controls and custom options, we deliver efficient belling machines that meet modern demands—no debugging required after installation.

- Suitable for PP/PE/PVC Pipe

- Pipe Diameter from 16mm to 1600mm

- R/U/Rectangle/Rieber Belling Type

- Semi-automatic/Automatic

- Modular Configuration

What Pipe Materials Can We Belled?

- Our belling machine heats and shapes PP, PE, and PVC pipes using specific temperatures and compatible belling modes for each material.

PP

- Polypropylene pipe

- 160-170°C processing temp

- R-type / U-type belling mode

PE

- Polypropylene pipe

- 200-240°C processing temp

- R-type / U-type belling mode

PVC/PVC-O

- Polyvinyl chloride pipe

- 170–190°C processing temp

- R / U / Rectangle /Rieber type belling mode

What Belling Modes Can We Provide?

- We provide R-type, U-type, Rectangle, and Rieber belling modes for secure, flexible, and efficient connections across various pipe types.

Rubber Type(R-type)

Rectangle Type

Smooth Type(U-type)

Rieber Type

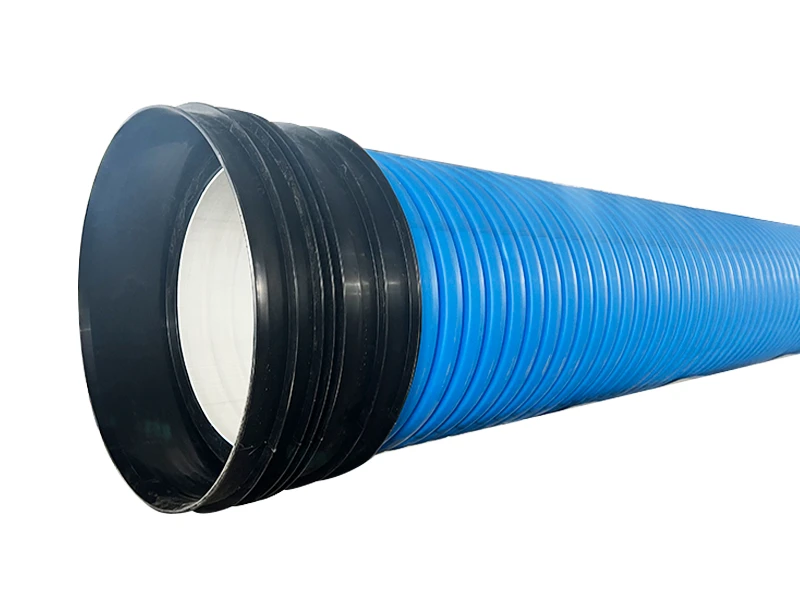

What Pipe Texture Can We Belled?

- In addition to belling smooth plastic pipes, we also offer belling machines for corrugated pipes and winding pipes, specialized equipment designed to form expanded socket ends on corrugated/wind pipes made of PVC, PP, or PE.

- Supported Single-wall/ double-wall corrugated and winding pipe

- Applies to pipe diameter range from 1/2” to 1200mm

- Rectangle (Square), R-type, U-type

- Internal expansion forming mode

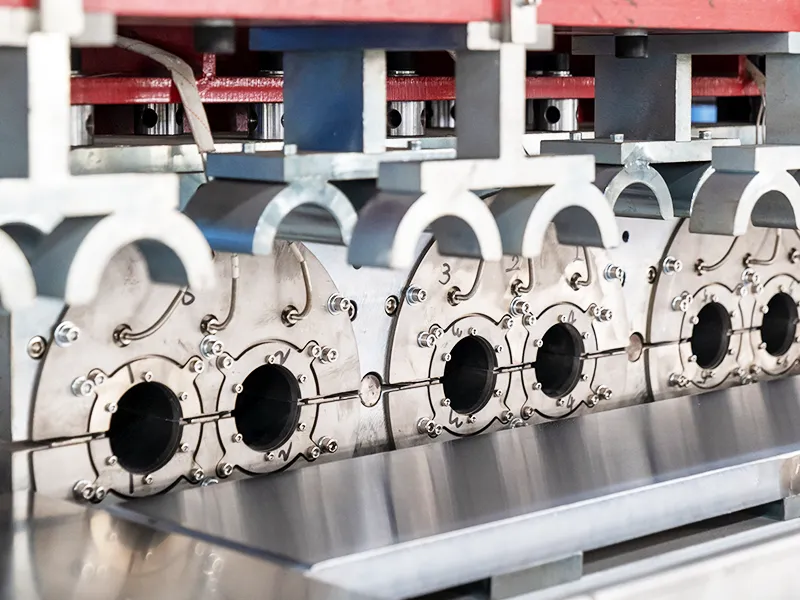

Need Specific Belling Capacity?

- Our belling capacity ranges from 1 to 12 pipes per cycle, handling diameters from 16mm to 110mm with U- or R-type ends.

Single Pipe Belling Machine

Double Pipe Belling Machine

Multiple Pipe Belling Machine

Get an Instant Quote and Production Plan

Guarantees clean finishes and stable socket forming.

What Operation Mode Can We Support?

- Our belling machine offers semi-automatic, and fully automatic modes to suit various production speeds, pipe sizes, and forming types.

Semi-automatic

Automatic

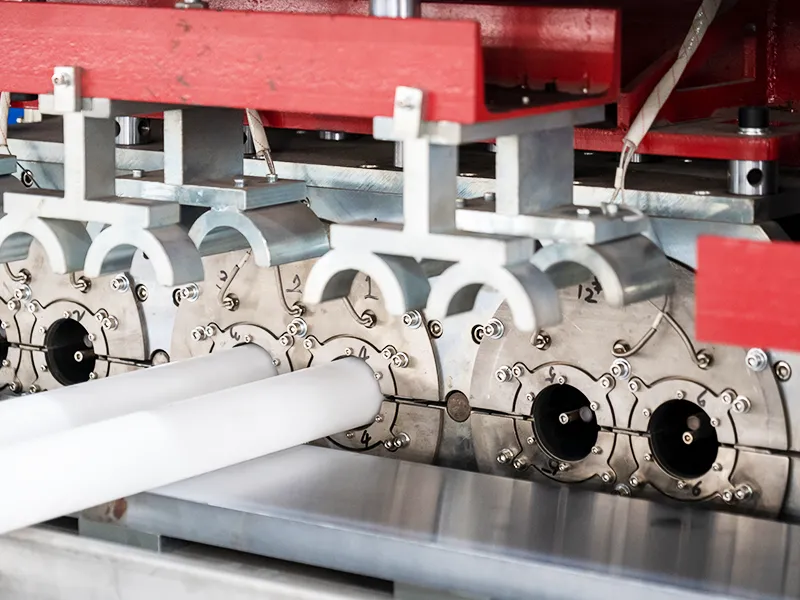

Belling Process of Our Belling Machine

- Pipe Feeding – Pipe is automatically or manually fed into the machine.

- Pipe Positioning – Pipe is accurately aligned for precise belling operation.

- Pipe Clamping – Pipe is clamped securely to prevent movement during belling.

- Heating Stage – Pipe end is heated to soften using internal or external heaters.

- Belling Forming – A mold or mandrel shapes the softened pipe into desired bell.

- Cooling Process – Bell is cooled using air or water to maintain formed shape.

- Mold Release – Mold retracts and releases the newly formed pipe bell.

- Pipe Ejection – Finished belled pipe is automatically or manually ejected from machine.

- Inspection Step – Bell shape and dimensions are checked for quality assurance.

Featured Products

DS250-NI Automatic Belling Machine

RBM 630 Rieber Belling Machine

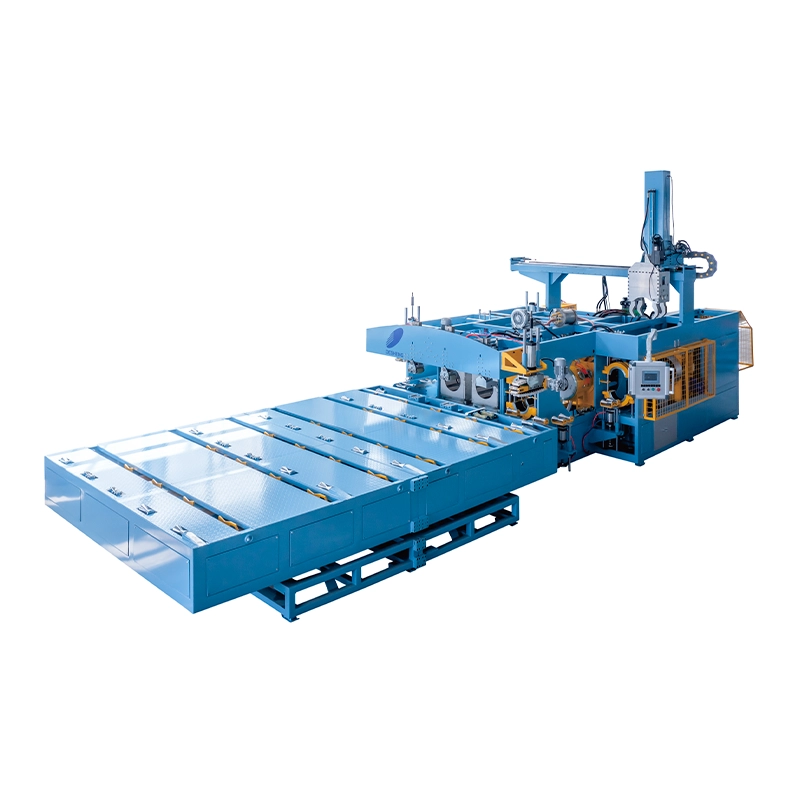

DS32-12 Automatic Multiple Pipe Belling Machine

PVC-O Pipe Belling Machine

Any Query? Let Us Know.

Frequently Asked Questions

Can your machines integrate with extrusion lines?

Yes. Our semi-automatic and fully automatic models can be synchronized with extrusion lines for continuous production.

What is the production speed of your belling machines?

Cycle times range from 15–180 seconds, with output from 20 to 400+ pipes/hour, depending on pipe size, material, and automation level.

What heating methods are used?

We use infrared or oven-ceramic heating, depending on the pipe material and belling type, to ensure efficient and even heating.

Can I customize machine functions for special socket profiles or standards?

Absolutely. We offer custom mold design and software customization to meet specific national or customer technical standards.

Do you ensure the products are delivered safely and securely?

We use high-quality export packaging, with special options for hazardous or temperature-sensitive goods; extra charges may apply.