DS400F Pipe Perforating Machine

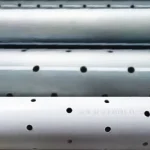

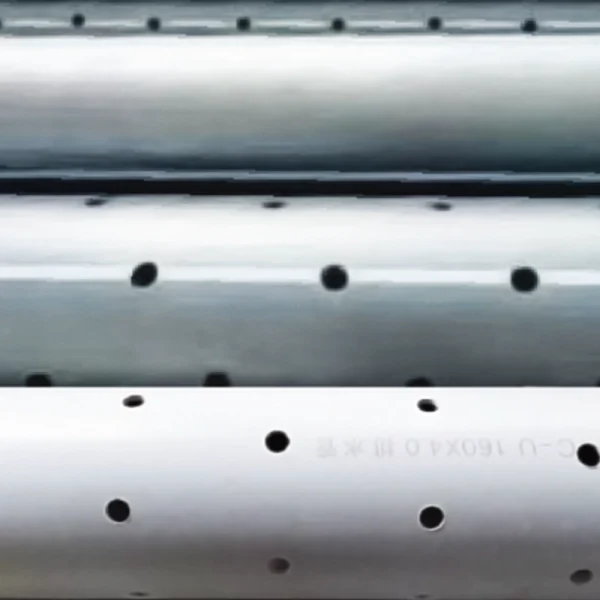

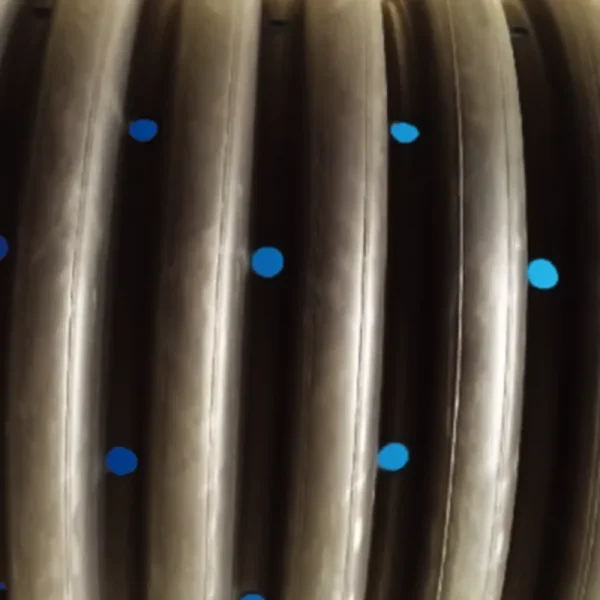

- Multi-Material Capability – Works with PVC, PE and PP pipes.

- Adjustable Hole Size & Pattern – Program hole diameters, spacing, and layouts.

- High-Speed Drilling – Achieves up to 200 holes/min with accurate positioning.

- Automated Feeding & Discharge – Reduces manual handling, improving efficiency.

- PLC Touch Screen Control – Easy operation with preset programs for different products.

Product Description

Our automatic pipe perforating machine ensures speed, precision, and flexibility, delivering consistent hole patterns with minimal burrs for manufacturers

With advanced automation and smart control systems, it integrates seamlessly into modern extrusion lines or operates as a stand-alone unit.

Work Principle

|

Optional Configurations

- Single-Side or Double-Side Perforation for different applications.

- Rotary Cutter or Multi-Spindle Heads for specific materials.

- Angle Drilling for specialized flow requirements.

- Offline or Inline Models based on production needs.

Seamless Integration with Automated Lines

Our pipe perforating machine is engineered for inline integration with extrusion, cutting, and belling machines. It communicates via a centralized PLC or SCADA system, enabling:

- Cycle synchronization to match upstream production speed.

- Automatic stoppage if upstream or downstream equipment encounters a fault.

- Real-time data sharing for MES systems, improving traceability and quality control.

- Technical Specifications

Product Parameters

| Model | DS400F |

| Diameter | φ110- φ400mm |

| Punching size | 10mm, 12mm, 20mm |

| Pipe Length | 3m-6m |

| Total power(KW) | 18KW |

| Machine type | Semi-automatic punching, capable of punching parallel or staggered holes |

| Puching mode | Vertical |