Bending plastic pipes is a core process in plumbing, drainage, industrial piping, and infrastructure projects. While fittings such as elbows and joints are widely used, precision pipe bending machines allow contractors and manufacturers to form smooth curves without increasing joint counts, reducing leakage points, and improving flow efficiency. At the heart of this process lies the heating system, which softens the pipe material so that it can be bent around a controlled radius without cracking or collapsing.

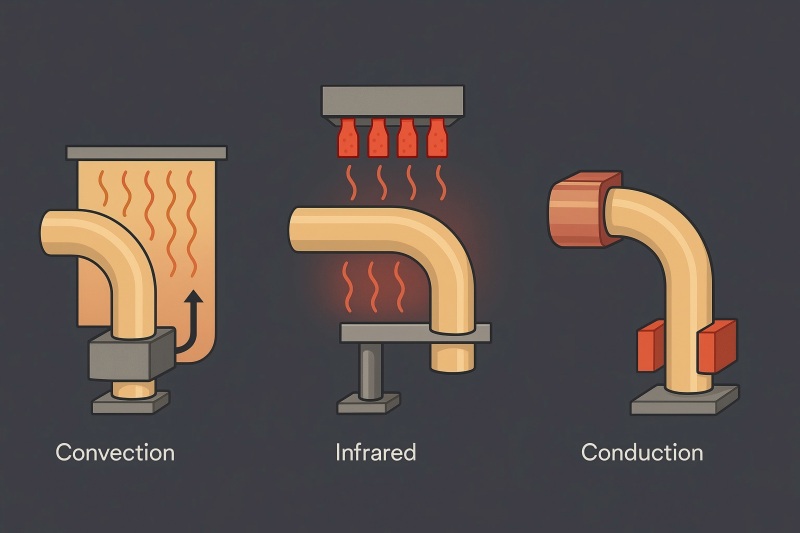

Different heating methods are employed in plastic pipe bending machines, each with unique characteristics that affect energy efficiency, bending accuracy, cycle time, material compatibility, and product quality. The three most common heating systems are Hot Air, Infrared (IR), and Resistance (Contact Heating).

Why Heating Systems Matter in Pipe Bending

Plastic pipes such as PVC (Polyvinyl Chloride), HDPE (High-Density Polyethylene), and PPR (Polypropylene Random Copolymer) are semi-crystalline or amorphous materials that become pliable within specific temperature ranges. To achieve consistent bends, the heating system must:

- Soften the pipe wall uniformly without overheating or underheating.

- Maintain material integrity by avoiding degradation or burns.

- Control cycle times to maximize production efficiency.

- Match energy efficiency requirements for long-term operational costs.

A poor heating system results in defects such as ovality, wall thinning, discoloration, warping, or cracking. Thus, selecting the right heating system is crucial for both quality and cost.

Overview of Heating Methods

Hot Air Heating

Uses blowers and heating elements to generate hot air, which circulates around the pipe.

Heat transfer occurs through convection.

Typically used for PVC pipes due to their narrow thermal window.

- Temperature Range: 80–200°C

- Applications: PVC electrical conduits, plumbing pipes, thin-walled pipes.

Infrared (IR) Heating

Employs infrared lamps or emitters to radiate energy directly onto the pipe surface.

Heat transfer occurs through radiation, absorbed by the pipe wall.

Provides fast, uniform heating across the circumference.

- Temperature Range: 100–350°C

- Applications: HDPE and PPR pipes with higher thermal resistance.

Resistance (Contact) Heating

Pipe comes into direct contact with heated metal plates, bands, or mandrels.

Heat transfer occurs through conduction.

Provides rapid heating but risks localized overheating.

- Temperature Range: 100–250°C

- Applications: Heavy-duty, thick-walled pipes where rapid heating is necessary.

Technical Comparison of Heating Systems

| Parameter | Hot Air | Infrared (IR) | Resistance (Contact) |

| Heat Transfer | Convection | Radiation | Conduction |

| Heating Speed | Slow–Moderate | Fast | Very Fast |

| Uniformity | Good (with circulation) | Excellent | Moderate (risk of hot spots) |

| Energy Efficiency | Medium | High | Medium |

| Temperature Control | Easy | Requires IR sensor feedback | Requires surface sensors |

| Maintenance | Low (fans, heaters) | Medium (lamp replacement) | High (wear on plates) |

| Safety | High (enclosed airflow) | Medium (exposed lamps) | Medium (hot plates) |

| Cost | Low | Medium–High | Medium |

| Best Material | PVC | HDPE, PPR | HDPE, PPR (thick walls) |

Energy Consumption and Cycle Time Analysis

Energy costs are a critical factor in pipe bending, especially for high-volume production lines.

| Heating System | Avg. Power Consumption (kW/hr) | Avg. Heating Time (per bend, min) | Efficiency Notes |

| Hot Air | 4.5 | 6–10 | Stable but slower |

| Infrared | 3.2 | 3–6 | Most energy-efficient |

| Resistance | 4.0 | 2–5 | Quick but higher localized losses |

Observations:

- Infrared heating provides the fastest cycle time per energy unit, making it highly suitable for large-scale operations.

- Hot air heating is slower but more forgiving for PVC pipes.

- Resistance heating is effective for thick-walled pipes but may consume more energy if poorly controlled.

Material Compatibility

PVC (80–105°C Softening Range)

- Works best with hot air because it heats gently and uniformly, preventing burning or discoloration.

- IR heating risks overheating due to PVC’s narrow thermal window.

- Resistance heating may cause localized damage.

HDPE (120–135°C Softening Range)

- Infrared heating is ideal—provides uniform heating, compensating for HDPE’s spring-back tendency.

- Resistance heating works for thick-walled HDPE but needs tight monitoring.

- Hot air is less efficient due to higher heat absorption requirements.

PPR (130–150°C Softening Range)

- Infrared is best for PPR due to uniform, fast heating.

- Resistance also works but requires controlled cooling to prevent wall thinning.

- Hot air is slow and less common in PPR bending.

Defect Prevention with Proper Heating

| Defect | Likely Cause | Heating System Most Susceptible | Prevention |

| Cracking | Uneven heating, too low temperature | Resistance | Maintain uniform surface heating |

| Discoloration | Overheating, thermal degradation | IR, Resistance | Use thermal sensors, avoid prolonged heating |

| Ovality | Non-uniform wall softening | Hot Air | Use air circulation fans |

| Wall Thinning | Excessive localized heating | Resistance | Mandrel support, lower heating intensity |

| Spring-back | Inadequate heating depth | Hot Air | Preheat longer, consider IR |

Cost-Benefit Analysis

| Factor | Hot Air | Infrared | Resistance |

| Initial Investment | Low | High | Medium |

| Operating Cost | Medium | Low | Medium |

| Maintenance | Easy | Moderate (lamp replacement) | High (surface wear) |

| Production Speed | Slow | Fast | Medium–Fast |

| Best ROI For | Small–medium factories | High-volume manufacturers | Specialized thick-walled applications |

Industrial Case Study

Case: 110mm HDPE Pipe Bending Line

Hot Air:

- Heating time = 8 min

- Energy per bend = 0.6 kWh

- Reject rate = 5%

Infrared:

- Heating time = 4 min

- Energy per bend = 0.35 kWh

- Reject rate = 2%

Resistance:

- Heating time = 3 min

- Energy per bend = 0.45 kWh

- Reject rate = 4%

Conclusion: Infrared heating provided the lowest cost per bend with highest quality consistency for HDPE.

Maintenance and Operational Considerations

Hot Air Systems

- Replace fans/heating elements periodically.

- Ensure filters are clean for airflow.

- Low risk of contamination.

Infrared Systems

- Lamps degrade over time; replace after ~5000–8000 hours.

- Requires calibration sensors for consistent heating.

- Sensitive to dust and surface reflectivity.

Resistance Systems

- Heating plates wear due to repeated contact.

- Risk of material residue buildup.

- Requires frequent cleaning and calibration.

Future Developments in Heating Technology

- Hybrid Systems: Combining hot air + IR for both speed and safety.

- Induction Heating: Emerging as a clean, fast, and controllable method for certain polymers.

- AI-Based Control: Adaptive feedback systems that adjust heating profiles in real time.

- Energy Recovery Systems: Capturing waste heat from resistance or IR for reuse.

The heating system is the core enabler of precision pipe bending machines. Choosing between Hot Air, Infrared, and Resistance heating depends on pipe material, production volume, energy cost, and quality requirements.

- Hot Air Heating is best for PVC due to its gentle, uniform temperature control.

- Infrared Heating is the most energy-efficient and suited for high-volume bending of HDPE and PPR.

- Resistance Heating is effective for specialized applications involving thick-walled pipes, though it requires tight control.

By aligning material compatibility, operational goals, and energy efficiency, manufacturers can ensure defect-free, cost-effective, and durable plastic pipe bending.