Pipe Threading Machine Manufacturer

- Our pipe threading machines can efficiently provide precise and clean threads for PVC and PE pipes of various sizes.

- Thread both the inside and outside of pipes with precision, enhancing sealing performance and connection reliability.

- 1/2”-630mm Pipe Diameter

- Pipe Thickness ≤10mm

- Support V-type and T-type Threads

- CNC Custom Thread Shape

Working Principle of Pipe Threading Equipment

- Secures the pipe firmly in place to prevent movement during threading.

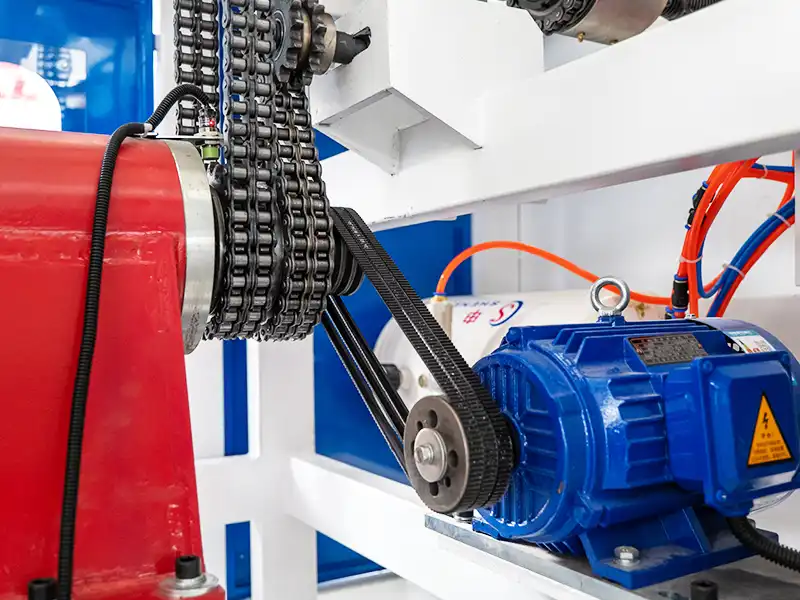

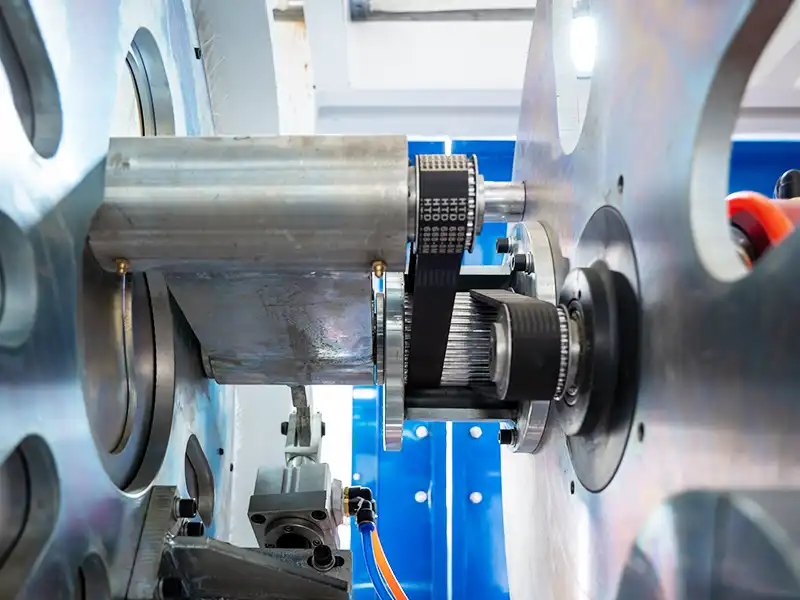

- Rotates the pipe or threading die using a motor-driven system.

- The threading die engages with the pipe end to cut precise threads.

- Threads are formed by gradually advancing the die onto the rotating pipe.

- Cooling fluid may be applied to reduce heat and prolong tool life.

- Machine stops automatically or manually when thread length is reached.

- The clamped pipe is released, ready for inspection or the next process.

What Pipe Material Can We Cut?

- Compatible with rigid PVC and soft PE pipes, ensuring clean threads on PVC and careful, low-pressure threading for PE.

PVC

PE

Cutting Position on the Pipe

Outer Thread

Inner Thread

Get an Instant Quote and Production Plan

Accurate cuts, clean finishes, long-lasting performance.

What Thread Types of Pipe Threaded Machine?

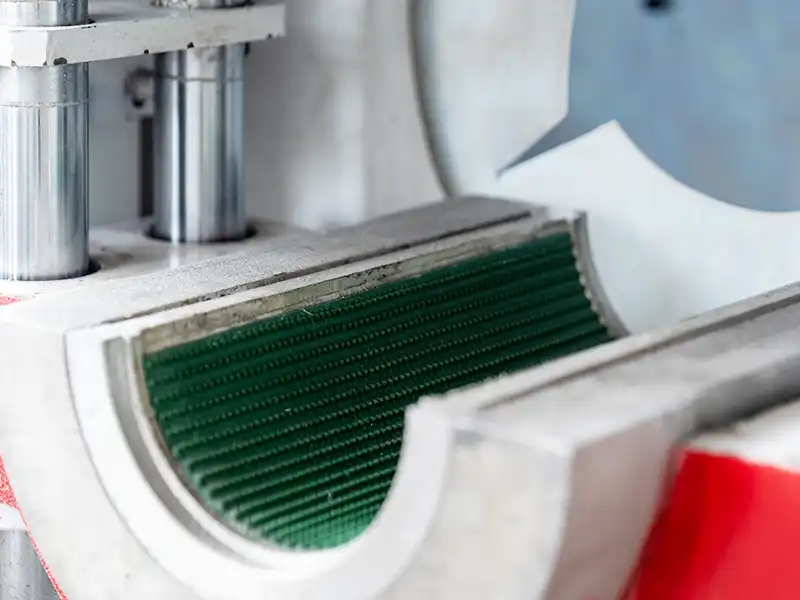

- Supports Triangular threads for tight sealing and Trapezoidal threads for strength, ideal for plastic pipe connections and load-bearing uses.

Triangular Thread

Trapezoidal Thread

What Can Our Threaded Pipe Machine Customize?

Pipe Diameter

Adjustable clamping systems for different outer diameters(1/2”-630mm).

Thread Size

Depth/fine/coarse pitch, customizable diameter for pipe threads.

Thread Shape

CNC customized threading for various pipe thread shapes.

Threading Direction

Right-hand or left-hand threading.

Control System

Semi-automatic, or fully automatic operation.

Automation Integration

Conveyor feeding, pipe cutting, chamfering, and ejection system

Any Query? Let Us Know.

Frequently Asked Questions

Can the machine cut both internal and external threads?

Yes, many models are capable of cutting both internal (female) and external (male) threads with the appropriate tooling.

What’s the maximum wall thickness the machine can cut?

Most machines can handle pipes with wall thicknesses up to 10mm. Thicker pipes require special settings or machines.

Does the machine require lubrication during threading?

Yes, using a coolant or cutting fluid is recommended to prevent overheating and ensure smoother threads.

How do I avoid cracking the pipe during threading?

Use proper clamping pressure, tool sharpness, and speed settings. Avoid overtightening the pipe in the chuck.

What maintenance is required?

Regular cleaning, lubrication, tool sharpening, and checking electrical components ensure long-term reliability.