In the world of pipe manufacturing, efficiency is key to maintaining competitive pricing, meeting production targets, and ensuring high-quality output. One essential tool in achieving these objectives is the belling machine. Belling machines are used in the production of pipes, specifically to form the bell-shaped end of pipes that allows for secure and leak-proof connections during installation.

What is a Belling Machine?

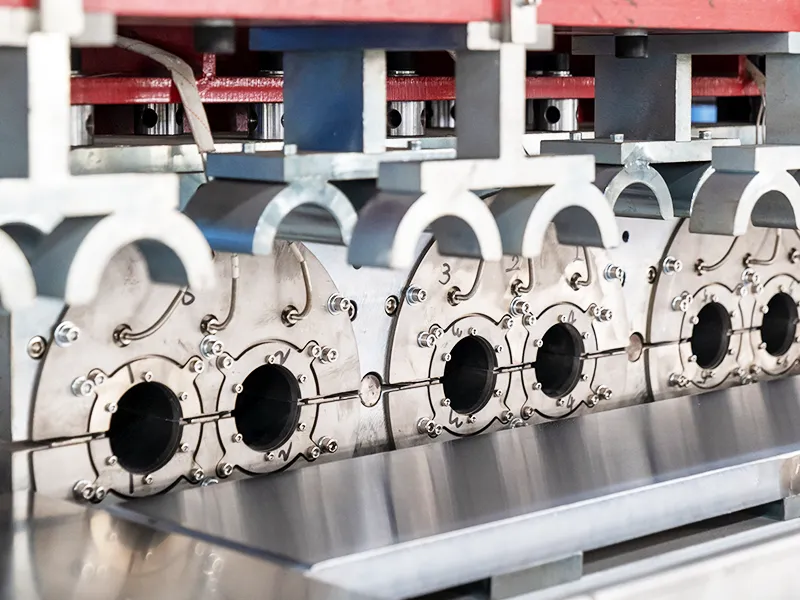

Before exploring cost-saving benefits, it’s important to understand belling machines. A belling machine is a specialized piece of equipment used to form a bell-shaped or flange end on pipes, typically made of PVC, HDPE, or other thermoplastic materials. This bell end is critical because it allows the pipe to be joined to another pipe using a rubber gasket or an elastomeric ring, ensuring a tight, durable, and leak-resistant connection.

The process of belling is a combination of heating, stretching, and molding. The belling machine softens the pipe’s end using heat, then forces it into a mold to form the bell shape. This process is quick, precise, and highly automated, which significantly contributes to cost reduction in pipe manufacturing.

Reducing Labor Costs

One of the primary ways belling machines help reduce production costs is through the reduction of labor requirements. Before the advent of belling machines, the process of forming pipe ends was typically a manual, labor-intensive task. Workers would have to heat and shape the ends of the pipes carefully, a process that was not only time-consuming but also prone to inconsistencies and errors.

With the automation provided by belling machines, much of this work is now done by machines, which significantly cuts down on the number of workers needed for each production run. Automated belling machines can form hundreds or even thousands of pipe bell ends per hour with minimal human intervention. This cuts labor costs and minimizes human error, ensuring consistent quality.

Labor Cost Savings with Belling Machines

| Process Type | Manual Process Costs | Automated Belling Machine Costs |

| Number of Workers Needed | 5-7 per shift | 1-2 per shift |

| Time per Pipe | 5-10 minutes | 1-2 minutes |

| Labor Cost per Shift | $500 | $100 |

| Output per Hour | 50-100 pipes | 500-1,000 pipes |

The increased output and faster processing time allow manufacturers to produce more pipes per hour while requiring fewer workers, which directly translates to lower labor costs.

Increasing Production Speed

Belling machines also reduce production costs by increasing the speed at which pipes are processed. In traditional pipe manufacturing methods, the time required to form each bell end could be quite long. This slow pace not only increases labor costs but also results in a decrease in overall productivity.

Automated belling machines, however, can form pipe bell ends in a matter of seconds. The combination of automation, precision heating, and high-speed molding enables manufacturers to create large volumes of pipe connections quickly and efficiently. This improved production speed directly contributes to reduced unit costs as more pipes can be produced within the same time frame.

Production Speed Comparison

| Process Type | Manual Process Speed | Automated Belling Machine Speed |

| Time to Form One Pipe | 5-10 minutes | 1-2 minutes |

| Pipes Produced per Hour | 50-100 | 500-1,000 |

| Production Time per Day | 8 hours | 8 hours |

| Total Pipes per Day | 400-800 | 4,000-8,000 |

The speed advantage of Belling machines is clear. By producing more pipes in less time, manufacturers can improve throughput and reduce the overall cost per unit, making their operations more cost-effective and competitive in the market.

Improving Accuracy and Minimizing Waste

Another key advantage of belling machines is their exceptional precision. In traditional methods, forming the bell end of pipes manually can lead to inconsistencies in size, shape, and quality. These inconsistencies may result in defective pipes that need to be scrapped or reworked, leading to increased material waste and higher production costs.

Belling machines, on the other hand, are highly precise, ensuring that each pipe end is formed to the exact specifications required for proper sealing and jointing. This accuracy lowers defect rates and cuts material waste, allowing more efficient use of raw materials.

Minimizing Energy Consumption

The energy efficiency of belling machines also plays a vital role in cost reduction. In traditional manual processes, the heating and shaping of pipe ends often require large amounts of energy, especially if the process is not optimized for efficiency. Additionally, manual heating methods can lead to inconsistent temperatures, which may cause the need for more energy to achieve the desired results.

Belling machines optimize energy efficiency, ensuring consistent and effective heating. Modern belling machines use precise temperature controls and advanced heating elements that minimize energy waste while providing the necessary heat to form the pipe ends. This optimization lowers energy usage, resulting in reduced manufacturing costs.

Long-Term Durability and Maintenance

Although belling machines represent an upfront investment, their long-term durability and low maintenance costs contribute to overall cost savings. Durable belling machines are engineered for long-term use, reducing repair needs and lowering overall ownership costs.

Moreover, belling machines’ automation reduces wear compared to manual processes. This leads to fewer breakdowns and reduced downtime, which can significantly impact overall production costs.

Conclusion

In the competitive world of pipe manufacturing, reducing production costs is essential to maintaining profitability and staying ahead of the competition. Belling machines play a crucial role in achieving this goal by automating the pipe end formation process, reducing labor costs, increasing production speed, enhancing precision, minimizing material waste, optimizing energy use, and offering long-term durability.

The initial investment in belling machines may be substantial, but the cost savings they provide through increased efficiency, reduced waste, and faster production times make them an invaluable asset to any pipe manufacturer. By leveraging the benefits of belling machines, manufacturers can not only reduce production costs but also improve product quality, increase output, and remain competitive in the ever-evolving market.