Belling machines are an essential part of plastic pipe production lines, responsible for forming the socket or “bell” at the end of pipes, enabling secure joints without extra fittings. Selecting the right belling machine has a direct effect on production efficiency, product quality, and overall operating costs.

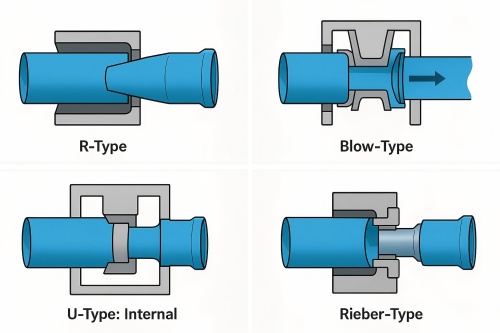

In modern manufacturing, four major types dominate the market: R-Type, Blow-Type, U-Type, and Rieber-Type. Each has unique forming methods, equipment requirements, and ideal applications.

Role of Belling in Pipe Production

In thermoplastic pipe production—especially PVC-U, CPVC, and PP-R—the belling stage is typically the final step after extrusion, cooling, and cutting. During belling:

- Pipe Heating – The pipe end is heated (using hot air or infrared heaters) to make it pliable.

- Mold Forming – The softened pipe end is expanded over a mold or inside a forming tool to create the socket shape.

- Cooling & Setting – The formed socket is cooled (often with air or water) to retain its precise dimensions.

A correctly belled socket ensures:

- Leak-proof joints

- Consistent fit with gaskets or adhesives

- Smooth assembly and disassembly in the field

The belling method chosen influences cycle time, energy consumption, product strength, and compliance with standards like EN 1401, ASTM D3034, or ISO 4435.

R-Type Belling Machines

How They Work

R-Type belling machines use a solid forming mandrel inserted into the heated pipe end. The mandrel expands the softened material to the desired bell size. A vacuum or light pressure may be applied to ensure a perfect mold fit.

Advantages

- Dimensional Accuracy – The rigid mandrel ensures exact bell diameters and uniform wall thickness.

- Smooth Inner Surface – Ideal for low-friction flow in sewer or drainage systems.

- Fast Cycle Time – Shorter forming duration compared to blow-type.

- Lower Energy Use – Reduced heating and cooling compared to air expansion.

Limitations

- Limited to specific bell shapes (mainly straight or slightly tapered).

- Not ideal for complex gasket grooves.

Ideal Applications

- Non-pressure PVC-U sewer and drainage pipes.

- Systems where smooth flow and tight tolerance are more important than gasket integration.

Blow-Type Belling Machines

How They Work

In blow-type belling, the heated pipe end is inserted into an external mold cavity. Compressed air is then blown inside the pipe, pushing the softened end outward against the mold walls to form the bell.

Advantages

- Handles Thick Walls & Large Diameters – Air pressure can expand heavier pipe sections evenly.

- Versatile Shapes – External mold can create various profiles.

- Strong Structural Integrity – Good for pressure-rated pipes.

Limitations

- Longer Cooling Time – Air-formed sockets often need extended cooling to avoid deformation.

- Higher Energy Use – Continuous compressed air supply adds operational cost.

- Potential for slight internal surface roughness compared to mandrel-formed bells.

Ideal Applications

- Large-diameter PVC or PP pressure pipes.

- High-pressure water supply lines.

U-Type Belling Machines

How They Work

The U-type process is a hybrid method: a mandrel expands the pipe end, but also shapes an internal gasket seat in one forming step. The bell has a U-shaped profile designed to hold sealing rings securely.

Advantages

- Integrated Gasket Seat – Eliminates separate machining for sealing grooves.

- Reliable Sealing Performance – Reduces leakage risk in pressurized systems.

- Fast Changeovers – Modular tooling for different diameters.

Limitations

- More complex tooling and mandrels compared to R-type.

- Limited suitability for very large diameters due to mandrel handling.

Ideal Applications

- Pressure and non-pressure systems requiring sealing rings (e.g., potable water, wastewater).

- Pipes meeting EN 681 or ISO 4633 gasket standards.

Rieber-Type Belling Machines

How They Work

The Rieber method uses a steel mandrel with an integrated groove form and often includes an in-line gasket installation system. The heated pipe is formed over the mandrel and cooled—while the gasket groove is precisely shaped and sometimes the gasket is directly inserted before cooling.

Advantages

- One-Step Forming + Gasket Placement – Reduces post-processing steps.

- High Consistency – Meets tight tolerances for premium sealing systems.

- Proven in Global Standards – Widely used in European and American potable water and wastewater systems.

Limitations

- Higher Initial Cost – More expensive machine and mandrel designs.

- Longer Setup for New Sizes – Each pipe size requires a dedicated high-precision mandrel.

Ideal Applications

- Municipal water and sewer systems.

- Projects requiring pre-installed gaskets for quick on-site assembly.

Comparative Analysis Table

| Feature / Factor | R-Type | Blow-Type | U-Type | Rieber-Type |

| Forming Method | Solid mandrel | Air pressure in mold | Mandrel + gasket seat shaping | Steel mandrel + groove, optional gasket install |

| Best For | Drain/sewer pipes | Large/thick pressure pipes | Gasketed pipes | High-precision gasketed pipes |

| Wall Thickness Handling | Thin to medium | Medium to thick | Medium | Medium |

| Gasket Integration | No | Possible (extra step) | Yes | Yes (integrated) |

| Cycle Time | Fast | Moderate | Fast | Moderate |

| Equipment Cost | Low | Medium | Medium | High |

| Changeover Speed | High | Medium | Medium | Low |

| Dimensional Precision | High | Medium-High | High | Very High |

| Energy Consumption | Low | High | Medium | Medium |

Choosing the Right Belling Machine for Your Production Line

When selecting between these four types, consider the following factors:

Pipe Specifications

- Material – PVC-U, CPVC, PP, or other thermoplastics have different heating and forming properties.

- Diameter Range – Large diameters often favor blow-type.

- Wall Thickness – Thick walls may require air expansion or specialized mandrels.

Joint Type

- If your system uses solvent welding, a simple R-type may be sufficient.

- For rubber ring joints, U-type or Rieber-type is preferred.

Production Volume

- High-volume, standard profile → R-type for cost efficiency.

- High-volume, gasketed → Rieber-type for integrated steps.

Standards & Certifications

Meeting EN, ISO, or ASTM standards may dictate the forming method (especially for potable water applications).

Budget & ROI

- Rieber-type requires higher upfront investment but reduces labor and increases assembly speed.

- Blow-type is versatile but may consume more energy.

Maintenance & Operational Considerations

Regardless of type, consistent performance depends on:

- Mandrel/Mold Maintenance – Wear can alter dimensions and cause leakage issues.

- Heating System Calibration – Incorrect heating leads to deformation or weak sockets.

- Cooling Efficiency – Fast, uniform cooling ensures dimensional stability.

- Operator Training – Skilled operators reduce waste and improve changeover times.

Choosing between R-Type, Blow-Type, U-Type, and Rieber-Type belling machines isn’t about which is “best” universally—it’s about which aligns with your pipe material, diameter, joint type, production volume, and quality requirements.

- R-Type: Best for fast, accurate sockets in drainage and sewer pipes.

- Blow-Type: Suited to large, thick-walled, or pressure-rated pipes.

- U-Type: Ideal for integrated gasket seats in sealing systems.

- Rieber-Type: Premium choice for integrated forming and gasket installation in high-specification markets.

By weighing performance, cost, and compatibility, you can select the belling machine that maximizes your production efficiency and delivers long-term value.