In the plastic pipe manufacturing industry, belling machines are critical for creating socket ends on pipes, enabling leak-proof joints and strong mechanical connections. The choice of belling machine directly impacts your production efficiency, socket quality, and long-term maintenance costs. One of the most decisive factors in machine selection is pipe diameter range.

From small-diameter conduit pipes to large-diameter sewer systems, each application requires a different approach to belling.

What are Belling Machines?

A belling machine is used to form the bell-shaped socket at the end of a thermoplastic pipe (such as PVC-U, CPVC, or HDPE) after extrusion. The bell end allows pipes to be joined without couplings, typically using rubber ring seals or solvent cement.

Key Working Principle:

- Heating:The pipe end is warmed until it reaches its softening point.

- Forming: A mold or mandrel shapes the softened pipe end into the desired socket profile.

- Cooling: The socket is cooled under controlled conditions to maintain dimensional stability.

Why Pipe Diameter Range Matters

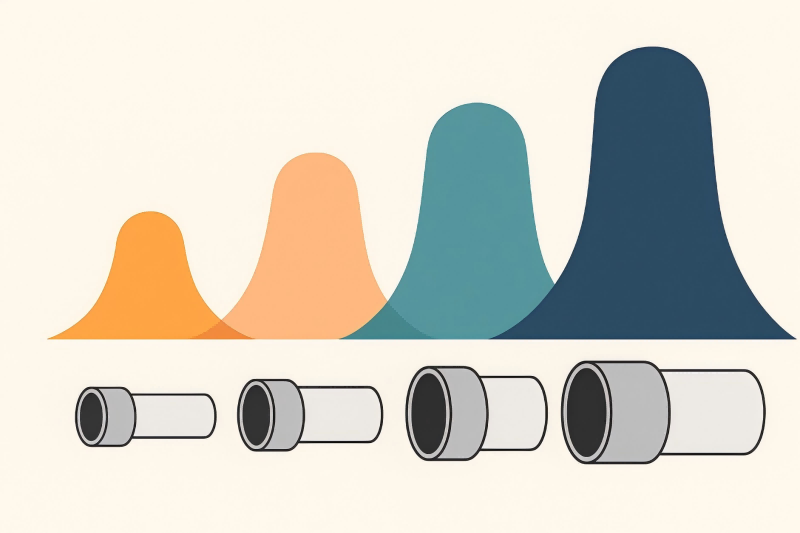

The pipe diameter range affects almost every aspect of belling machine selection:

- Forming Mechanism: Small-diameter machines use more compact molds, while large-diameter machines require heavy-duty, multi-stage forming.

- Heating Method: Larger diameters require longer heating cycles or more powerful heaters to ensure even softening.

- Clamping and Handling: Large pipes need stronger clamping systems and possibly automated handling to maintain alignment.

- Cycle Time: Bigger diameters often mean longer cycle times unless compensated with advanced heating and cooling systems.

Common Diameter Ranges and Applications

| Diameter Range | Common Applications | Example Materials | Socket Type Commonly Used |

| 16–63 mm | Electrical conduit, small water supply pipes | PVC-U, CPVC | Solvent cement |

| 75–160 mm | Domestic water supply, small drainage systems | PVC-U, CPVC, HDPE | Solvent cement, rubber ring |

| 200–400 mm | Urban water mains, medium drainage systems | PVC-U, HDPE | Rubber ring |

| 500–1200 mm | Large sewer, industrial water transport | PVC-U, HDPE | Rubber ring, custom sealing systems |

Types of Belling Machines by Diameter Range

Small-Diameter Belling Machines (16–63 mm)

- Pros: Compact footprint, faster cycle times, lower power consumption.

- Cons: Limited versatility for larger pipe projects.

- Best for: High-speed production lines for conduit or small pressure pipes.

Medium-Diameter Belling Machines (75–160 mm)

- Pros: Versatile for residential and light commercial use, can handle both solvent and rubber ring sockets.

- Cons: May require changeover kits for switching between materials.

- Best for: Manufacturers with diverse orders.

Large-Diameter Belling Machines (200–400 mm)

- Pros: Robust construction, capable of deep socket formation.

- Cons: Larger footprint, higher capital cost.

- Best for: Municipal water supply and medium drainage systems.

Extra-Large-Diameter Belling Machines (500–1200 mm)

- Pros: Heavy-duty forming capability, advanced cooling systems.

- Cons: High investment cost, slower cycle time without advanced heating.

- Best for: Industrial-scale sewage and stormwater projects.

Data-Driven Considerations for Selection

| Feature / Factor | Small Diameter | Medium Diameter | Large Diameter | Extra-Large Diameter |

| Typical Pipe OD (mm) | 16–63 | 75–160 | 200–400 | 500–1200 |

| Heating Cycle (sec) | 10–20 | 15–30 | 25–50 | 40–90 |

| Average Output (pcs/hr) | 500–800 | 300–500 | 150–250 | 60–120 |

| Machine Power (kW) | 5–10 | 8–15 | 15–25 | 25–40 |

| Typical Cost (USD) | $20,000–$40,000 | $40,000–$70,000 | $70,000–$120,000 | $120,000–$250,000 |

Heating and Cooling Methods

- Hot Air Heating: Ideal for small and medium diameters; ensures even heating without burning the surface.

- Infrared Heating: Faster for larger diameters; reduces cycle time.

- Water Cooling: Common for small diameters due to shorter cycles.

- Air Cooling: More practical for large diameters to avoid rapid thermal stress.

Material Compatibility

- PVC-U: Most common for potable water and drainage; compatible with all belling machine sizes.

- CPVC: Higher temperature resistance; requires more precise heating control.

- HDPE: Requires different forming pressure due to higher elasticity.

Automation and Production Volume

If you produce large batches in a narrow diameter range, a dedicated high-speed belling machine is most cost-effective.

If you produce multiple diameters in smaller volumes, a versatile machine with quick-change tooling will save downtime.

ROI and Cost-Benefit Analysis

For a medium-sized plant producing 160 mm PVC-U pipes, upgrading from a manual-changeover belling machine to an automatic multi-diameter model can:

- Cut changeover time from 45 minutes to less than 10 minutes.

- Increase daily output by up to 20%.

- Lower labor requirements by 1–2 operators per shift.

Quick Selection Guide Table

| Your Diameter Range | Recommended Machine Type | Output Focus | Investment Level |

| 16–63 mm | High-speed single-socket automatic | Speed | Low–Medium |

| 75–160 mm | Multi-diameter automatic | Flexibility | Medium |

| 200–400 mm | Heavy-duty semi-automatic | Strength | Medium–High |

| 500–1200 mm | Customized hydraulic automatic | Reliability | High |

Practical Tips Before Purchase

- Assess Current and Future Demand – Avoid over-investing in extra-large capacity you may never need.

- Check Tooling Availability – Ensure the manufacturer offers molds for all planned diameters.

- Review After-Sales Support – Downtime due to lack of spare parts can be more costly than initial savings.

- Energy Efficiency – Newer models can cut power consumption by up to 15%, lowering long-term operating costs.

- Test with Your Material – Especially important if you produce CPVC or modified PVC pipes.

Choosing the right belling machine for your pipe diameter range is not just about matching sizes—it’s about balancing speed, flexibility, investment, and future scalability. By carefully analyzing your product mix, production targets, and material requirements, you can select a belling machine that maximizes your return on investment while maintaining high-quality output.