In modern plastic pipe production, achieving smooth coordination between the belling machine and the pipe extrusion line is critical for ensuring stable output, minimizing downtime, and maintaining product quality. A mismatch between these two key components can lead to production bottlenecks, product defects, or excessive energy consumption.

Why Matching Matters in Pipe Production

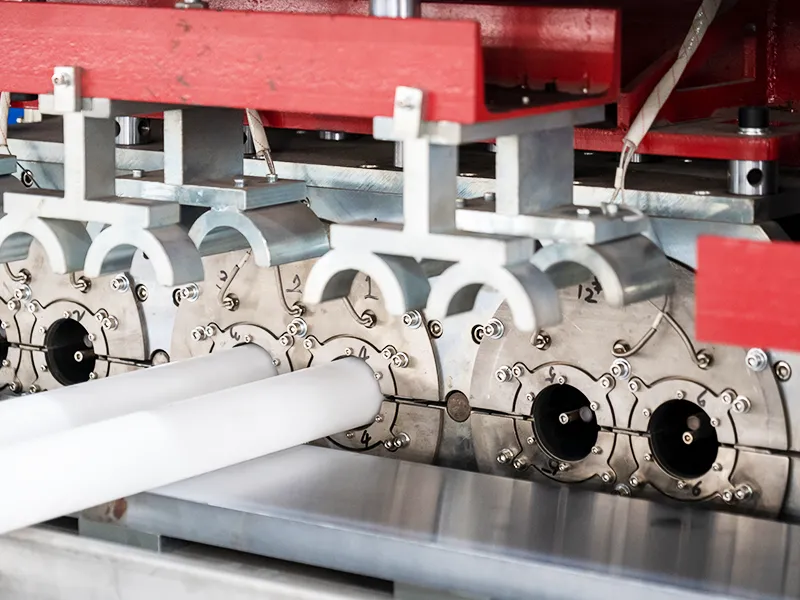

The belling machine is typically placed at the end of the extrusion line. Its role is to create a socket (bell) at one end of the pipe, enabling easy connection during installation. While extrusion lines run continuously, belling machines work on each individual pipe length, which involves several steps—cutting, heating, belling, cooling, and discharge.

If the extrusion speed is higher than the belling machine’s processing capacity, pipes will accumulate, requiring buffer storage or causing line stoppages. On the other hand, if the belling machine is too fast, it will often be forced to idle, wasting energy and increasing wear without increasing output.

- Efficient matching ensures:

- Continuous production flow without interruption.

- Optimized energy use and equipment lifespan.

- Uniform pipe quality with correctly formed sockets.

- Higher overall productivity and reduced operator intervention.

Key Parameters of Extrusion Speed

Extrusion speed depends on several factors:

- Pipe diameter and wall thickness

- Extruder output capacity (kg/h)

- Die head design and cooling length

- Line speed settings (m/min)

For example:

- A 50 mm PVC pipeline may run at 15–20 m/min.

- A 160 mm line may operate around 5–8 m/min.

- A 400 mm line may run at only 1.5–3 m/min due to cooling requirements.

This line speed determines how quickly finished pipe lengths reach the downstream belling machine.

Key Parameters of Belling Machine Capacity

Belling machine capacity is measured in pieces per minute (pcs/min) or cycle time per pipe. It depends on:

- Heating time to soften the pipe end.

- Belling time to expand and shape the socket.

- Cooling time to stabilize the shape.

- Machine type (inline vs. offline, single vs. double socket station).

For example:

- A small-diameter automatic belling machine may process up to 10–12 pcs/min.

- A large-diameter machine may process only 2–4 pcs/min due to longer heating and cooling cycles.

The cycle time per pipe typically includes:

- Cycle time = loading time + heating time + belling time + cooling time + unloading time

Calculating the Matching Ratio

The matching between extrusion speed and belling capacity can be expressed as:

Belling Capacity (pcs/min)≥Extrusion Speed (m/min)/Pipe Length (m)

Example 1: Small Diameter Line (63 mm PVC)

- Extrusion speed: 15 m/min

- Pipe length: 6 m

- Required belling machine capacity = 15 / 6 = 2.5 pcs/min

If the belling machine can process 4 pcs/min, the matching is good.

Example 2: Large Diameter Line (250 mm PVC)

- Extrusion speed: 3 m/min

- Pipe length: 6 m

- Required belling machine capacity = 3 / 6 = 0.5 pcs/min

If the belling machine processes 1 pcs/min, the capacity is sufficient. But if heating takes too long, accumulation may occur.

Practical Tip:

- For efficient operation, the belling machine capacity should be 10–20% higher than the extrusion output, to allow for variation and avoid bottlenecks.

Inline vs. Offline Belling Systems

Inline Belling Machines

- Installed directly after the cutting unit.

- Work in sync with the extrusion line.

- Ideal for high-speed small- to medium-diameter production.

- Require precise synchronization with line speed.

- Reduce handling, labor, and storage costs.

Offline Belling Machines

- Operate independently, processing cut pipes in batches.

- Suitable for large-diameter pipes where heating/cooling takes longer.

- Allow flexible scheduling but require extra space and handling.

For inline systems, matching capacity is critical to avoid production delays. For offline systems, the belling machine can operate at its own pace, but total daily throughput must still match extrusion output over time.

Synchronization Strategies

Servo-Controlled Speed Matching

Modern belling machines use servo systems that synchronize the pulling speed with the extrusion line. If the line slows down or speeds up, the belling machine adjusts automatically.

Buffer Conveyors

Adding accumulation conveyors between the cutter and beller allows for minor mismatches. Pipes can queue briefly without stopping the line, absorbing fluctuations.

Multi-Socket Stations

For high-speed lines, using a dual-station or twin-socket belling machine doubles capacity without increasing cycle time per socket.

Optimized Heating Zones

Upgrading heating ovens with infrared or hot-air circulation systems can reduce heating time, increasing cycle capacity without mechanical modifications.

Factors Influencing Heating & Cooling Time

The belling cycle is often limited by heating and cooling, especially for thick-walled or large-diameter pipes.

| Parameter | Effect on Heating Time | Effect on Cooling Time |

| Pipe diameter ↑ | Longer heating required | Longer cooling required |

| Wall thickness ↑ | Slower heat penetration | Longer shape stabilization |

| Heating technology | Infrared is faster than convection | N/A |

| Cooling technology | N/A | Water spray is faster than air |

| Socket shape | Complex shapes need more time | Longer cooling to avoid deformation |

Optimizing these factors is key to increasing belling capacity without buying new equipment.

Case Study: 110 mm PVC Pressure Pipe Line

- Extrusion Speed: 10 m/min

- Pipe Length: 6 m

- Required Capacity: 10 / 6 = 1.67 pcs/min

Existing belling machine:

- Heating: 10 s

- Belling: 4 s

- Cooling: 10 s

- Loading/unloading: 6 s

- Total cycle time: 30 s → 2 pcs/min

This machine matches the extrusion line with a 20% buffer, allowing stable inline operation without accumulation.

Selecting the Right Belling Machine

When selecting a belling machine to match your extrusion line:

| Criteria | Small Diameter | Large Diameter |

| Machine Type | Inline automatic | Offline batch or inline with buffer |

| Capacity | High pcs/min | Lower but sufficient |

| Heating System | Infrared or short-cycle | Longer heating, uniform |

| Cooling | Air or water spray | Extended cooling section |

| Control | Fully synchronized with line | Independent or semi-automatic |

Tip: For multi-line factories, choosing machines with adjustable heating and cycle settings helps adapt to different products easily.

Advanced Matching Solutions

Intelligent PLC Control

Modern PLCs allow for real-time capacity monitoring. If the extrusion line accelerates, the PLC can automatically shorten heating time slightly or activate standby sockets to keep pace.

Modular Machine Design

Some manufacturers offer modular belling machines that can be expanded with extra socket stations or upgraded heaters to increase capacity later as production grows.

Energy Recovery Systems

Integrating heat recovery from ovens to preheat incoming pipe ends can reduce cycle time and energy use simultaneously.

Common Mismatch Problems and Solutions

| Problem | Cause | Solution |

| Pipe accumulation before beller | Belling too slow | Upgrade heating, add buffer, or slow extrusion |

| Machine idle often | Belling too fast | Adjust extrusion speed or combine two extrusion lines |

| Deformed sockets | Cooling too short | Extend cooling or reduce line speed |

| Irregular bell shape | Temperature fluctuation | Upgrade heating control and synchronization |

Practical Matching Example Table

| Pipe Size (mm) | Extrusion Speed (m/min) | Pipe Length (m) | Required Belling Capacity (pcs/min) | Typical Belling Machine |

| 50 | 20 | 6 | 3.3 | Inline, 6–8 pcs/min |

| 110 | 10 | 6 | 1.67 | Inline, 2–3 pcs/min |

| 160 | 6 | 6 | 1.0 | Inline, 1.5–2 pcs/min |

| 250 | 3 | 6 | 0.5 | Offline, 0.8–1 pcs/min |

| 400 | 2 | 6 | 0.33 | Offline, long heating |

Final Checklist for Efficient Matching

- Calculate required belling capacity based on line speed and pipe length.

- Select appropriate machine type (inline vs offline) based on diameter and speed.

- Ensure heating and cooling cycles are optimized for your pipe dimensions.

- Use servo synchronization or buffer systems for smooth flow.

- Monitor capacity regularly to adjust for material or speed changes.

Conclusion

Matching the belling machine capacity to the pipe extrusion speed is a fundamental step in achieving efficient, stable, and profitable plastic pipe production. By understanding the cycle time structure, calculating capacity requirements, and applying synchronization strategies, manufacturers can avoid costly mismatches and maximize line performance.

As a professional belling machine manufacturer, we design and supply customized inline and offline belling solutions for various pipe diameters and materials. Whether you’re upgrading an existing line or installing a new extrusion system, we help ensure that your belling capacity and extrusion speed work in perfect harmony for seamless production.