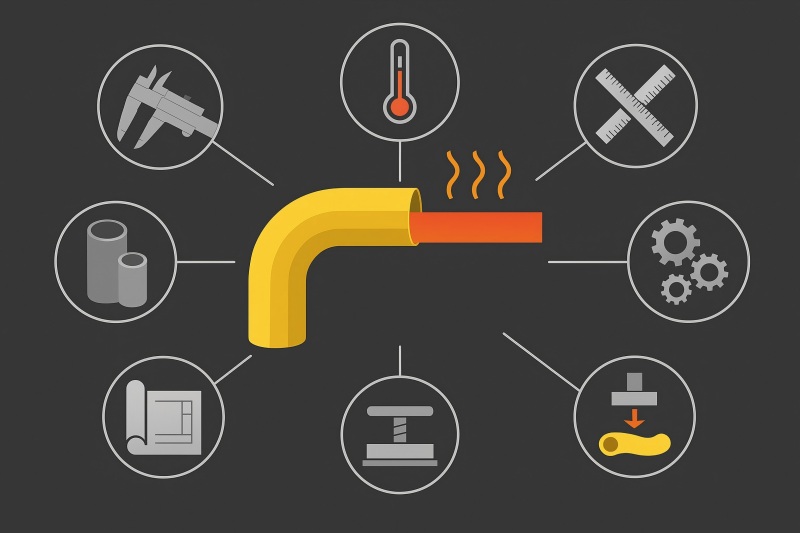

Accurate pipe bending is one of the most critical processes in plastic pipe manufacturing, impacting product consistency, structural strength, and downstream assembly. Whether producing PVC electrical conduits, PP/PPR plumbing fittings, PE irrigation pipes, or custom plastic profiles, bending precision directly affects the performance and quality of the final product.

Bending Precision in Plastic Pipe Manufacturing

Industrial plastic pipe bending machines—whether hot air, infrared, oil-circulating, or servo-controlled—do more than simply apply heat and shape the pipe. Precision depends on tightly controlling temperature, mechanical alignment, bending radius, clamping pressure, and material behavior. Even small deviations can lead to defects such as:

- Ovality

- Wall thinning

- Kinking

- Wrinkles

- Inconsistent curvature

- Spring-back

- Surface whitening or burn marks

Understanding the factors that affect these outcomes is essential for achieving high-quality, repeatable, and stable bending results.

Material Properties and Their Influence on Bending Accuracy

Material Type: PVC, PP, PE, PPR, ABS

Different plastics soften, melt, and deform at different temperature ranges. Their bending response varies widely:

| Material | Typical Bending Temperature | Behavior Characteristics |

| PVC | 110–140°C | Good formability, prone to surface whitening if overheated |

| PP | 140–160°C | Higher flexibility, higher spring-back |

| PE | 120–140°C | Very flexible, difficult to maintain sharp bending geometry |

| PPR | 130–155°C | Ideal for plumbing bends; stable but sensitive to overheating |

| ABS | 90–110°C | Easy to bend but prone to deformation if underheated |

Material selection affects:

- Required heating time

- Bending resistance

- Shrinkage after cooling

- Final radius accuracy

Manufacturers must tailor machine parameters for each polymer type.

Wall Thickness and Diameter

Thicker walls retain heat longer and tolerate higher bending loads, producing more stable bends. However:

- Thin-walled pipes (below 2.5 mm) easily deform or collapse

- Large diameters require stronger clamping force

- Small diameters must be heated evenly to avoid soft spots

Incorrect settings lead to ovality, flattening, or bending angle inconsistency.

Plasticization and Thermal Memory

All thermoplastics retain “thermal memory”—a tendency to revert partially after bending. This creates spring-back, reducing angle accuracy. Materials with higher molecular mobility like PE and PP have more spring-back compared with PVC or ABS.

Temperature Control: The Most Critical Factor in Precision Bending

Temperature affects plastic elasticity, molecular structure, flow behavior, and bending response.

Heating Uniformity

If the heating zone is not evenly heated:

- One side softens more than the other

- Warping or twisting occurs

- Curvature deviates along the pipe length

Industrial pipe bending machines solve this using:

- Multi-zone heating elements

- Infrared reflectors

- Hot air circulation

- Contact heating molds

- Temperature feedback sensors

Uniformity is the key to achieving identical bends across batches.

Underheating

When the pipe core temperature is lower than required:

- Material resists bending

- Stress concentration forms at the curve

- Cracks or whitening appear

- Bend radius becomes inaccurate

Underheated pipes show inconsistent curvature because internal and external layers deform at different rates.

Overheating

Excessive temperature causes:

- Wall thinning

- Surface burn marks

- Loss of structural strength

- Pipe ovality or flattening

Overheating also reduces dimensional stability, leading to unpredictable post-cooling shrinkage.

Heating Time and Cooling Time

Inaccurate timing creates problems:

- Too short: insufficient softening → cracking

- Too long: thermal degradation → deformation

- Improper cooling: uneven shrinkage → bend distortion

Servo-controlled and PLC-based bending machines allow precise timing control for stable, repeatable results.

Mechanical Factors That Influence Bending Precision

Bending Radius Design

Each plastic type requires a minimum bend radius, usually measured as multiples of its outer diameter.

- PVC: 6–10 × OD

- PP: 8–12 × OD

- PE: 10–15 × OD (very flexible but hard to stabilize)

Attempting to bend below the recommended radius leads to:

- Kinks

- Collapse

- Ovalization

- Angle deviation

Accurate mold and mandrel design ensure stable curvature.

Clamping Pressure and Alignment

Clamping and feeding precision determine whether the pipe remains centered and stable during bending.

If clamping pressure is too low:

- Pipe slips

- Angle deviates

- Bend position drifts

If too high:

- Indentations form

- Pipe becomes flattened

High-quality machines use:

- Servo-driven clamps

- Adjustable jaws

- Pressure-regulated hydraulic or pneumatic systems

These maintain consistent pressure across the bending cycle.

Mandrel Type and Support Tools

For round pipe bending, support tools (mandrels, internal springs, external formers) are essential.

Internal mandrels prevent:

- Pipe collapse

- Ovality

- Excessive spring-back

External molds ensure the curvature matches design specifications, especially for tight-radius bends.

Feeding Accuracy and Servo Control

Servo-driven feeding systems greatly improve bending precision:

- Accurate pipe length positioning

- Stable speed control

- Repeatable angle accuracy (±0.1° in advanced systems)

- Improved consistency across long production runs

Cheap mechanical or pneumatic feeders cannot maintain such tolerance.

Machine Structure and Technology Factors

Machine Frame Rigidity

If the bending machine frame is weak or vibrates under load:

- Angle changes

- Curvature drifts

- Repeatability decreases

Robust steel frames reduce vibration and ensure stable machine alignment.

Heating Technology (Hot Air / Infrared / Oil Circulation / Electric Mold)

Different heating systems provide different levels of temperature control:

| Heating Method | Precision Level | Notes |

| Infrared Heating | ★★★★ | Fast heating, good consistency |

| Hot Air Heating | ★★★ | Common but prone to uneven heating |

| Oil-Circulating Heating Mold | ★★★★★ | Highest precision and temperature stability |

| Electric Mold Heating | ★★★★★ | Very stable, best for tight radii |

Choosing the right heating technology directly impacts bending accuracy.

Control System and Automation Level

Machines with PLC or CNC control allow operators to program:

- Bending angles

- Heating profiles

- Rotation degrees

- Cooling cycles

- Multi-angle sequences

This reduces human error and ensures uniform results.

Tooling Wear and Molding Accuracy

Tooling plays a major role in repeatable bending precision. Worn or poorly machined molds cause:

- Angle deviation

- Dimensional inconsistency

- Surface defects

Regular inspection and precision CNC machining of tools are essential.

Environmental and Operational Variables

Ambient Temperature

In colder environments:

- Material needs longer heating

- Cooling becomes too rapid

- Spring-back increases

In hot environments:

- Pipes soften too early

- Dimensional stability drops

Machines equipped with temperature compensation help maintain accuracy.

Humidity and Storage Conditions

Moisture affects some plastics (e.g., nylon, some ABS blends):

- Dimensional expansion

- Softness variation

- Mechanical instability

Proper storage improves bending consistency.

Operator Skill and Calibration

Human factors remain important even with automation:

- Incorrect calibration → angle drift

- Improper tool placement → deformation

- Poor control of heating time → defects

Well-trained operators and standard operating procedures significantly improve bending quality.

Common Bending Defects and Their Engineering Causes

| Defect | Cause | Engineering Solution |

| Ovality | Too much clamping pressure, insufficient mandrel support | Use larger mandrel, adjust pressure |

| Wrinkles | Overheating, improper radius | Improve temperature control, increase bend radius |

| Spring-back | Material memory, underheating | Increase heating temperature, adjust overbend angle |

| Cracking | Underheating, sharp radius | Increase heating time, use preheating |

| Surface whitening | Excessive internal stress | Lower bending speed, optimize heating zone |

| Angle deviation | Poor feeding accuracy | Switch to servo control |

Engineering Recommendations to Improve Bending Precision

Use Servo-Driven Bending Machines

Servo systems offer:

- ±0.1° angle accuracy

- Consistent repeatability

- Smooth bending motion

Ideal for high-volume industrial production.

Apply Multi-Zone Temperature Control

Zonal heating ensures:

- Uniform softening

- Less warping

- Reduced surface defects

Especially important for large-diameter pipes.

Use Proper Internal Support Tools

Mandrels and springs dramatically reduce:

- Ovality

- Collapse

- Wall thinning

Optimize Bend Radius Based on Material

Use recommended minimum bending radii and adjust tooling accordingly.

Maintain Rigorous Tool Inspection Cycles

Worn tooling causes unpredictable errors. CNC-refinished molds restore precision.

Implement Standard Calibration Routines

Daily or weekly calibration ensures consistency across batches.

Future Trends in Plastic Pipe Bending Precision

The industry is adopting newer technologies to enhance accuracy:

AI-Based Heating Control

Sensors and AI algorithms automatically adjust heating intensity to:

- Material variations

- Pipe thickness

- Ambient temperature

Digital Twin Bending Simulation

Simulates deformation before actual bending, improving tooling design.

Closed-Loop Servo Feedback

Continuously monitors bending angle and automatically corrects deviations in real time.

Conclusion

Bending precision in plastic pipe manufacturing depends on an interconnected set of engineering factors—including temperature control, material properties, mechanical stability, machine design, and operator skill. By optimizing these variables, manufacturers can achieve consistent, accurate, and high-quality bending results that meet the demands of plumbing, HVAC, automotive, electrical conduit, and industrial applications.