Belling machines play a crucial role in pipe manufacturing. These machines are essential in the production of high-quality pipes that can withstand the demands of various industries, from construction to infrastructure development and sewage systems.

By creating precisely molded ends, belling machines enhance the strength, durability, and longevity of pipes, ensuring that they perform reliably in the toughest environments.

What is a Belling Machine?

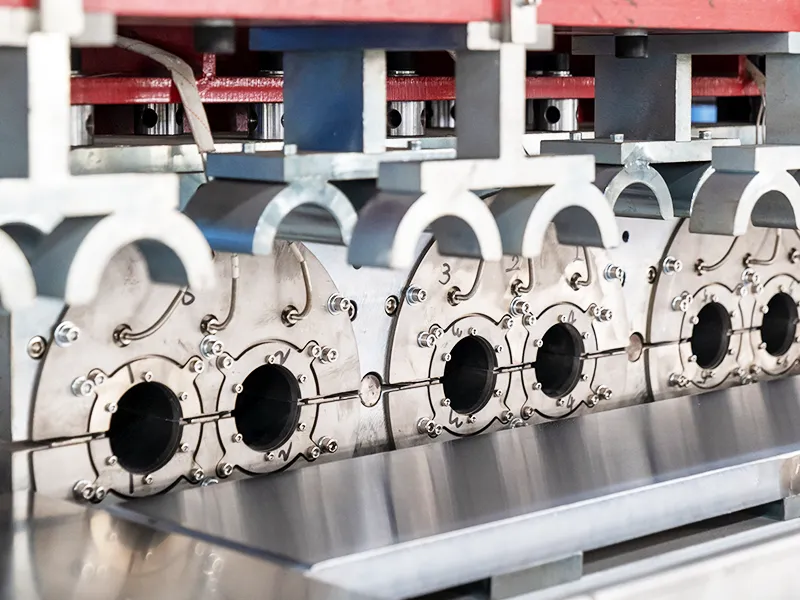

A belling machine shapes bell ends on pipes during manufacturing. The process of “belling” involves expanding the end of a pipe, creating a flared, socket-like shape that allows for easy and secure jointing with other pipes. This feature is crucial in applications such as sewer systems, water pipelines, and gas transportation networks, where a reliable, tight connection is necessary to prevent leaks and ensure the stability of the system.

The belling process is used for thermoplastic pipes like PVC, HDPE. The belling machine works by heating the pipe end and then using mechanical pressure or hydraulic force to mold it into the desired bell shape.

How Belling Machines Enhance Pipe Strength and Durability

Securing Tight, Leak-Proof Joints

One of the primary benefits of using a belling machine is its ability to create tight, secure joints between pipes. The bell shape produced by the belling machine allows another pipe to fit snugly into it, often with the help of rubber gaskets or other sealing elements. This ensures that the connection is not only mechanically strong but also resistant to leakage. In industries where pipes are used to carry hazardous liquids, gases, or wastewater, the importance of leak-proof joints cannot be overstated. Belling machines create tight seals, improving pipe system integrity.

Enhancing Pipe Flexibility and Resistance to External Forces

Belling machines enhance pipes’ resistance to pressure, vibration, and movement. The process of belling also increases the flexibility of the pipe joint, allowing it to better absorb stresses that might otherwise cause damage. This is especially important in applications like underground water systems, where pipes are subject to shifting soil conditions or the impact of heavy machinery. The flexibility afforded by the bell end ensures that the pipe can endure such forces without cracking or breaking.

Increasing the Load-Bearing Capacity

The bell end of the pipe also enhances its load-bearing capacity. By expanding the pipe at the end, the belling machine creates a stronger structural connection, which can better handle the weight and pressure exerted by surrounding soil or other external forces. This is crucial for underground pipes, which endure significant weight.

Additionally, the belling process can improve the resistance of the pipe to bending and deformation under load. In applications like trenchless installations or pipe bursting, where pipes must endure significant bending during installation, the bell-shaped ends provide extra reinforcement, making the pipe more durable and capable of withstanding these challenges.

Improving Resistance to Corrosion and Wear

Pipes used in harsh environments, such as wastewater systems or chemical transport pipelines, need to be resistant to corrosion and wear. The belling process plays a role in ensuring that the pipe remains durable over time. By forming a uniform and smooth bell shape, belling machines help reduce areas where stress concentrations might lead to cracks or weak spots in the pipe. These cracks can later become entry points for corrosive substances, accelerating wear and tear on the pipe material.

Moreover, the precise and consistent formation of the bell end reduces the risk of manufacturing defects that could contribute to early pipe failure. This level of quality control helps improve the overall resistance of the pipe to corrosion, wear, and other forms of degradation.

Technological Advancements in Belling Machines

Belling machines have significantly advanced in technology over time. These improvements have led to increased efficiency, precision, and overall performance. Modern belling machines now feature advanced control systems, automated adjustments, and high-speed processing capabilities that allow manufacturers to produce pipes with greater consistency and less waste.

Computer Numerical Control (CNC) Technology

The integration of CNC technology into belling machines has revolutionized the pipe manufacturing process. CNC-controlled belling machines allow for precise control over the belling process, including temperature, pressure, and molding speed. This ensures that the pipe ends are formed with extreme accuracy, reducing the potential for defects and improving the overall strength and durability of the final product. Manufacturers can also customize pipe sizes and specifications more easily with CNC-based machines, enhancing their ability to meet the demands of different industries.

Hydraulic and Electric Drive Systems

Newer belling machines often utilize advanced hydraulic and electric drive systems, which offer more precise control over the belling process. These systems allow for better regulation of the amount of force applied during belling, ensuring that the pipe is not overstretched or deformed in any way. This results in a more consistent and stronger bell end, improving the pipe’s performance in real-world applications.

Faster Processing and Improved Efficiency

Modern belling machines are designed to operate at higher speeds than their predecessors, which increases productivity in pipe manufacturing. With improved automation and faster cycle times, manufacturers can produce more pipes in a shorter amount of time while maintaining high standards of quality. This efficiency lowers costs and meets the rising demand in industries.

Enhanced Materials Handling

New belling machines are also equipped with advanced materials handling systems that help improve the overall efficiency of the pipe manufacturing process. These systems automate pipe loading and positioning, reducing labor and errors. The result is a more streamlined production process that produces higher-quality pipes with less downtime.

Applications of Belling Machines in Pipe Manufacturing

Belling machines are used extensively in the production of a wide range of pipes, including those made from PVC, HDPE, and other thermoplastic materials. Below are some common applications:

| Pipe Type | Common Applications |

| PVC Pipes | Used in plumbing, irrigation, and sewage systems. Ideal for low to medium-pressure systems. |

| HDPE Pipes | Commonly used in gas and water distribution, as well as underground piping systems. |

| Concrete Pipes | Used in stormwater drainage, sewers, and large infrastructure projects. |

| PE Pipes | Used for gas supply systems, water pipes, and industrial applications. |

Belling machines are vital in each of these applications, ensuring that pipes can be securely joined, sealed, and installed in various environments.

Belling machines play a crucial role in the pipe manufacturing process by enhancing the strength, durability, and reliability of pipes. Through the creation of precisely formed bell-shaped ends, these machines improve the jointing process, increase the load-bearing capacity, and make pipes more resistant to corrosion, wear, and external forces. With ongoing technological advancements, modern belling machines are more efficient, precise, and capable of producing high-quality pipes that meet the demands of industries ranging from construction to wastewater management. As such, belling machines continue to be an indispensable tool in the production of pipes that are critical to infrastructure development around the world.