Pipe bending is an essential manufacturing process across industries such as automotive, HVAC, construction, shipbuilding, furniture, fitness equipment, and metal fabrication. As factories expand capacity and move toward automation, choosing the right bending machine becomes a key strategic decision.

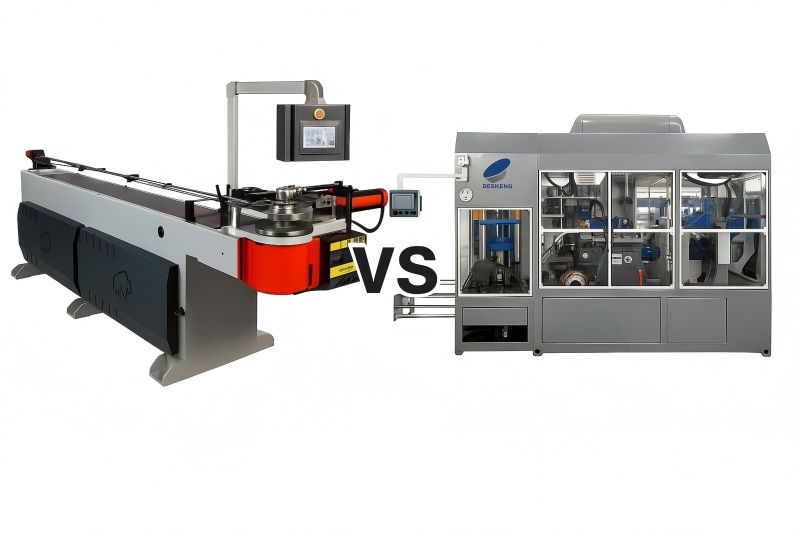

The two mainstream options—automatic and semi-automatic pipe bending machines—offer distinct advantages depending on your production volume, product types, material requirements, and workforce structure.

Understanding the Two Machine Types

Before analyzing the differences, it’s important to understand the fundamental characteristics of each machine.

What Is a Semi-Automatic Pipe Bending Machine?

A semi-automatic pipe bender typically includes:

- Hydraulic or electric bending systems

- Basic manual operation

- Preset angle input through a simple control panel

- Manual feeding and positioning

- Single-axis control (bending only)

The operator manually loads the pipe, sets the angle, positions the workpiece, and activates each bend step. These machines fit low-to-medium production needs, offering flexibility and a low initial investment.

What Is an Automatic Pipe Bending Machine?

Automatic or CNC pipe bending machines include:

- Servo-controlled multi-axis movement

- Automatic feeding, rotation, and bending

- Pre-programmed bending sequences

- Multi-radius or multi-layer bending

- Automatic clamping, mandrel control, and unloading

- Stack programming for repeated production

- High precision (±0.1° or better)

They reduce manual labor significantly and ensure consistent results, making them ideal for high-precision, repetitive production lines.

Automatic vs Semi-Automatic Pipe Benders Compared

This section outlines the primary engineering and operational differences that affect machine selection.

Production Speed and Throughput

Automatic Machine

- Eliminates manual feeding

- Performs multi-angle bending automatically

- Delivers continuous cycles without operator downtime

- Can run long sequences from a single program

- Ideal for mass production

Typical Output:

Up to 2–5x faster than semi-automatic models for the same pipe geometry.

Semi-Automatic Machine

- Requires operator input for each step

- More downtime between cycles

- Slower for complex multi-bend parts

- Best for low-volume or custom jobs

Conclusion:

If speed and throughput matter, automatic machines hold a clear advantage.

Precision and Repeatability

Automatic Machine

- Servo motors maintain consistent feeding and rotation

- Digital control ensures angle accuracy

- Ideal for high-precision parts like automotive exhausts, HVAC coils, and aerospace tubing

Precision levels can reach:

- ±0.1° angle accuracy

- ±0.1 mm feeding accuracy

Semi-Automatic Machine

- Operator skill influences accuracy

- Manual positioning introduces variations

- Suitable for parts with simple geometry and wider tolerance requirements

Precision levels:

±1° or greater, depending on operator skill

Conclusion:

Automatic machines offer unmatched repeatability for tight tolerances.

Labor Cost and Workforce Skill Requirements

Semi-Automatic

- Requires more skilled operators

- Labor makes up a large share of total production costs.

- Human error risk is higher

- Operator fatigue influences quality

Automatic

- Requires one supervisor for several machines

- Lower human involvement reduces labor cost

- Easy programming makes the process repeatable

- Suitable for factories with limited skilled labor

Conclusion:

Automatic machines reduce dependency on skilled operators and are better for long-term labor efficiency.

Complexity of Pipe Geometry

Automatic Machines Handle:

- Multi-bend sequences

- Different radius combinations

- Complex 3D geometries

- Thin-walled tubing requiring controlled mandrel operation

- Programmable rotation angles

- Multi-layer stacked bending

These characteristics make them essential for industries such as:

- Automotive exhaust and chassis

- Aerospace hydraulic line

- Marine engineering

- Fitness equipment

- HVAC evaporator coils

Semi-Automatic Machines Handle:

- Simple bends

- Single-radius tubes

- Short production runs

- Small-batch customization

Conclusion:

Automatic machines excel in complex geometry production, while semi-automatic machines suit simpler tasks.

Material Compatibility and Stability

Some materials—such as stainless steel, aluminum alloy, thin-walled copper, or titanium—require:

- Controlled bending speed

- Multi-stage pressure regulation

- High-precision rotation and feeding

- Mandrel support synchronization

Automatic machines perform better with these materials because:

- Servo systems control speed precisely

- Mandrel movement synchronizes automatically

- Pressure settings are programmable

- Spring-back is easier to compensate for

Semi-automatic machines may cause:

- Ovality

- Wrinkling

- Kinks

- Inconsistent bend angle

Conclusion:

For difficult or expensive materials, automatic machines protect the pipe structure and reduce scrap rates.

Cost Comparison: Initial vs. Long-Term Investment

Understanding cost differences helps factories plan budgets effectively.

Initial Investment

Semi-Automatic Machine:

✔ Lower upfront cost

✔ Ideal for startups or occasional production

✔ Fewer electronic components

Automatic Machine:

✔ Higher initial investment

✔ Includes servo motors, advanced software, CNC control, sensors

Price differences can range from 2–5 times, depending on model complexity.

Long-Term Operational Cost

Automatic machines deliver:

- Lower labor cost

- Lower scrap rate

- Higher output per hour

- Less downtime

- Higher ROI over time

Semi-automatic machines incur more long-term costs due to:

- More manual labor

- Lower productivity

- Higher energy usage for certain hydraulic models

- Greater variation leading to quality rework

Conclusion:

Semi-automatic is cheaper initially, but automatic machines often become more cost-effective within 1–3 years.

Safety, Stability, and Maintenance Requirements

Safety Features

Automatic machines typically include:

- Servo-controlled feed

- Automatic clamping & release

- Collision detection

- Overload protection

- Emergency stop systems

- Auto-lubrication systems

Semi-automatic machines rely more heavily on operator judgment, increasing accident risks.

Stability and Maintenance

Automatic Machines

- Require regular calibration

- Software updates

- Servo motor maintenance

- Higher machine structure rigidity

- Suitable for high-duty cycles

Semi-Automatic Machines

- Easier maintenance

- Fewer components

- Lower repair cost

- More mechanical wear due to manual adjustment

Conclusion:

Automatic machines offer better long-term stability but require technical maintenance.

Best Use Cases for Each Machine Type

When to Choose a Semi-Automatic Pipe Bending Machine

Choose semi-automatic if your factory:

- Produces small batches

- Manufactures simple pipe shapes

- Requires flexibility for different job types

- Has skilled workers available

- Operates in a low-budget environment

- Produces custom or on-demand orders

- Uses thick-walled or easy-to-bend materials (mild steel, larger diameters)

Typical Industries

- Small metal workshops

- Furniture fabrication

- Custom handrail production

- Small automotive repair shops

- HVAC installation contractors

When to Choose an Automatic Pipe Bending Machine

Choose automatic if your factory:

- Produces high-volume orders

- Handles complex multi-bend 3D pipe shapes

- Works with expensive or thin-walled materials

- Requires high repeatability and precision

- Wants to reduce skilled labor dependency

- Plans to scale or automate production

- Needs digital monitoring or smart manufacturing integration

Typical Industries

- Automotive OEM & aftermarket

- Aerospace manufacturing

- Shipbuilding

- High-end furniture manufacturing

- Fitness equipment factories

- Hydraulic systems and power engineering

- Refrigeration and HVAC coil manufacturing

Technical Comparison Table

| Factor | Automatic Pipe Bending Machine | Semi-Automatic Pipe Bending Machine |

| Precision | ★★★★★ ±0.1° | ★★★ ±1° |

| Speed | Fast, continuous | Moderate, operator-dependent |

| Labor Demand | Low | High |

| Material Compatibility | Excellent for all materials | Limited for thin-wall or complex metals |

| Complex Geometry | Fully supported | Limited |

| Initial Cost | High | Low |

| Long-Term ROI | High | Moderate |

| Scrap Rate | Low | Higher |

| Programming | Complete CNC control | Manual setting |

| Suitable For | Mass production | Small batches, simple bends |

How to Decide Which One Fits Your Factory

To make the best decision, evaluate your factory based on:

Production Volume

If monthly output is high, automatic is more cost-effective.

Product Complexity

Multi-bend 3D parts require CNC automation.

Material Type

Thin-walled stainless steel, copper, or aluminum require automatic machines.

Labor Availability

Automatic machines help offset the shortage of skilled workers.

Budget & ROI Timeline

Semi-automatic machines are budget-friendly; automatic machines pay off faster in volume production.

Factory Automation Goals

If your factory aims to integrate Industry 4.0 technologies, automation is essential.

Conclusion

Choosing between automatic and semi-automatic pipe bending machines depends on your factory’s production needs, workforce, material types, and long-term growth plans. Semi-automatic machines provide flexible, affordable simplicity for low-volume production. Automatic pipe benders, however, offer superior accuracy, efficiency, and consistency—making them the best choice for modern factories aiming to scale production and improve competitiveness.