In modern plastic pipe production lines, every stage—from extrusion and cooling to cutting and packaging—plays a vital role in ensuring product quality and production efficiency. Among these processes, chamfering often receives less attention than extrusion or socketing. However, chamfering is essential for improving pipe end quality, facilitating installation, and ensuring long-term pipeline performance.

For manufacturers producing PVC, PE, or PP pipes for plumbing, drainage, irrigation, or cable protection, integrating a plastic pipe chamfering machine into the production line is not merely optional—it’s a critical step toward meeting modern market standards and installation requirements.

What Is Chamfering in Plastic Pipe Production?

Chamfering refers to the process of creating a beveled edge at the end of a plastic pipe after cutting. This bevel is typically at an angle of 15° to 45°, depending on the pipe specification and application. Chamfering can be performed on one end or both ends of the pipe.

In plastic pipe systems—especially for socket and spigot joints, rubber ring sealing joints, and solvent-welded joints—the chamfered end helps guide the pipe smoothly into the socket, minimizing damage to sealing rings and ensuring tight, leak-free connections.

Key Chamfering Applications

- PVC Pressure Pipes: Chamfering ensures proper insertion into gasketed sockets.

- Sewer and Drainage Pipes: Facilitates push-fit assembly and maintains sealing integrity.

- Irrigation Pipes: Simplifies field installation by reducing manual preparation time.

- Electrical Conduits: Prevents cable damage during installation by softening sharp edges.

Why Chamfering Matters in Production Lines

Chamfering may seem like a simple finishing operation, but its effects ripple across production efficiency, installation performance, and overall product reliability.

Improved Pipe Joining and Sealing

A properly chamfered end ensures the rubber sealing ring in the socket remains undamaged during pipe insertion. This reduces joint failures, leakage risks, and costly rework during installation.

Reduced Installation Time

Without chamfering, workers must manually file or grind pipe edges on-site, slowing down assembly. Automated chamfering in the production line delivers installation-ready pipes, saving time and labor.

Enhanced Aesthetic and Product Quality

A uniform chamfer gives the pipe end a clean, professional appearance. This is especially important for visible installations or high-specification projects where aesthetics and consistency are valued.

Minimized Pipe Damage

Sharp cut edges can damage fittings, gaskets, or cables. Chamfering eliminates these risks, extending the service life of both pipes and accessories.

Chamfering Techniques in Plastic Pipe Production

Chamfering can be performed in several ways depending on production speed, pipe diameter, material type, and equipment configuration. The table below summarizes the main methods.

| Chamfering Method | Description | Suitable For | Advantages | Limitations |

| Manual Chamfering | Using hand tools to bevel pipe ends individually | Small workshops, low volume | Low equipment cost, flexible | Inconsistent results, slow speed |

| Offline Automatic Chamfering | Chamfering after cutting in a separate station or machine | Medium to large pipes, moderate speed | Accurate angles, improved consistency | Extra handling required |

| Inline Automatic Chamfering | Integrated into the production line, usually combined with belling or cutting units | High-volume PVC or PE pipe lines | High efficiency, perfect repeatability, saves labor | Higher machine cost, needs precise synchronization |

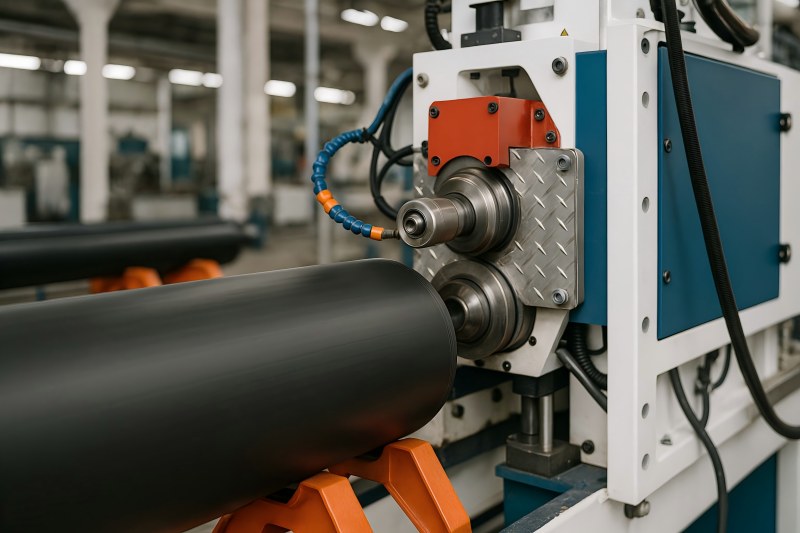

Inline chamfering machines are most commonly used in modern high-speed extrusion lines. They can be standalone units placed after the saw, or integrated into belling machines to perform chamfering and socketing simultaneously.

Integration Points in the Production Line

Chamfering typically takes place immediately after the cutting station and before socketing or stacking. Below is a typical sequence of a PVC pipe production line with chamfering integration:

Extrusion → 2. Cooling Tank → 3. Haul-off → 4. Cutting Unit → 5. Chamfering Station → 6. Belling Machine (Socketing) → 7. Stacking / Packaging

Some production lines combine cutting and chamfering in a single machine, while others install a separate chamfering unit. The choice depends on production speed, space availability, and product specifications.

Inline vs. Offline Integration

- Inline: Chamfering is synchronized with pipe extrusion, cutting, and socketing, minimizing handling and ensuring uniform quality.

- Offline: Pipes are collected and transferred to a separate chamfering station. Suitable for specialized sizes or retrofitted lines.

Chamfering Machine Features and Selection

Manufacturers should evaluate key features carefully when choosing the ideal plastic pipe chamfering machine.

| Feature | Importance | Remarks |

| Diameter Range | Determines compatibility with product line | Typical range: 16 mm – 800 mm |

| Number of Chamfering Heads | Single or double ends, affects speed | Dual-head machines increase throughput |

| Chamfering Angle Adjustability | Allows different pipe standards | Common angles: 15°, 30°, 45° |

| Synchronization with Cutting | Crucial for inline integration | Should support extrusion line speed |

| Dust Extraction | Ensures clean chamfer and reduces debris in joints | Especially important for PVC |

| Servo or Pneumatic Drive | Affects precision and maintenance | Servo-driven preferred for high precision |

Modern machines also feature PLC control, touchscreen interfaces, and automatic adjustment systems for different pipe diameters, improving flexibility and reducing changeover time.

Chamfering Standards and Specifications

Chamfering must comply with relevant national and international standards, depending on the pipe application. For example:

- EN 1401: Specifies a 15° chamfer on PVC-U pipes designed for underground drainage applications.

- ISO 4422: Recommends chamfering to avoid gasket damage in pressure pipes.

- ASTM D3034: States chamfering requirements for PVC sewer pipes to ensure proper gasket sealing.

Typical chamfer dimensions:

- Angle: 15°–45°

- Length: 2–6 mm (depending on diameter and standard)

- Edge finish: Smooth, free from burrs or sharp edges

Impact on Production Efficiency

Integrating chamfering into the production line delivers measurable efficiency improvements:

- Reduced Manual Labor: Eliminates on-site chamfering work.

- Shorter Production Cycle: Inline chamfering synchronizes seamlessly with cutting.

- Fewer Rejects: Precise chamfers reduce joint failures and product returns.

- Faster Packaging: Pipes are delivered installation-ready, improving downstream logistics.

For example, a medium-sized PVC pipe manufacturer producing 500 pipes per day saved 2–3 minutes per pipe in field installation by integrating inline chamfering. Over time, this translated into significant labor savings for their customers, improving competitiveness.

Safety and Maintenance Considerations

Chamfering machines operate with rotating cutters or blades, so safety measures are crucial:

- Protective Enclosures: Prevent accidental contact with rotating tools.

- Emergency Stop Switches: Accessible from operator positions.

- Dust Collection Systems: Prevent inhalation hazards and ensure clean bevels.

- Regular Blade Sharpening: Dull blades reduce chamfer quality and accelerate tool wear.

- Routine Calibration: Ensures angles and lengths remain within tolerance.

Scheduled maintenance minimizes downtime and extends machine life.

Emerging Trends in Chamfering Technology

As plastic pipe production lines become more automated and faster, chamfering technology is evolving as well:

- CNC-Controlled Chamfering Units: Offer automatic diameter adjustment and angle setting for flexible production runs.

- Integrated Chamfering–Belling Stations: Combine multiple finishing steps, reducing footprint and synchronization issues.

- Sensor-Based Quality Control: Inline vision systems verify chamfer angle and smoothness, ensuring consistent output.

- Energy-Efficient Drives: Servo motors replace pneumatics for precision and reduced energy use.

These trends help manufacturers achieve higher output, lower energy consumption, and better compliance with quality standards.

Practical Example: Chamfering in a PVC Pipe Line

Let’s consider a real-world scenario:

A manufacturer produces PVC-U pipes with diameters from 90 mm to 315 mm for underground drainage. The production line runs at 6 m/min, with a cutting saw and belling machine at the end.

By integrating an inline double-head chamfering unit between the cutting and belling stations, the factory achieved:

- Consistent 15° chamfers on both pipe ends.

- Zero gasket damage during installation.

- 30% reduction in installation time on construction sites.

- Elimination of manual deburring at the belling station.

The chamfering unit required minimal additional floor space and was fully synchronized with the extrusion speed using PLC control.

Cost Considerations

Chamfering machines represent a moderate investment relative to their impact on product quality and production efficiency. Costs vary depending on:

- Pipe diameter range

- Number of heads (single vs double)

- Automation level: manual, semi-automatic, or PLC-controlled

- Integration complexity

While a basic offline chamfering machine may cost a few thousand dollars, a fully integrated inline double-head chamfering system may cost significantly more. However, the ROI is often achieved quickly through reduced labor, lower defect rates, and faster installation.

Chamfering is far more than a cosmetic finishing operation. In plastic pipe production lines, it plays a pivotal role in ensuring leak-free joints, efficient installation, and high-quality end products.

By selecting the right chamfering technique, integrating it strategically into the production line, and maintaining equipment properly, manufacturers can enhance both productivity and customer satisfaction.

As the industry embraces automation, precision chamfering will continue to be a critical process for PVC, PE, and PP pipe producers seeking to maintain a competitive edge in quality and efficiency.