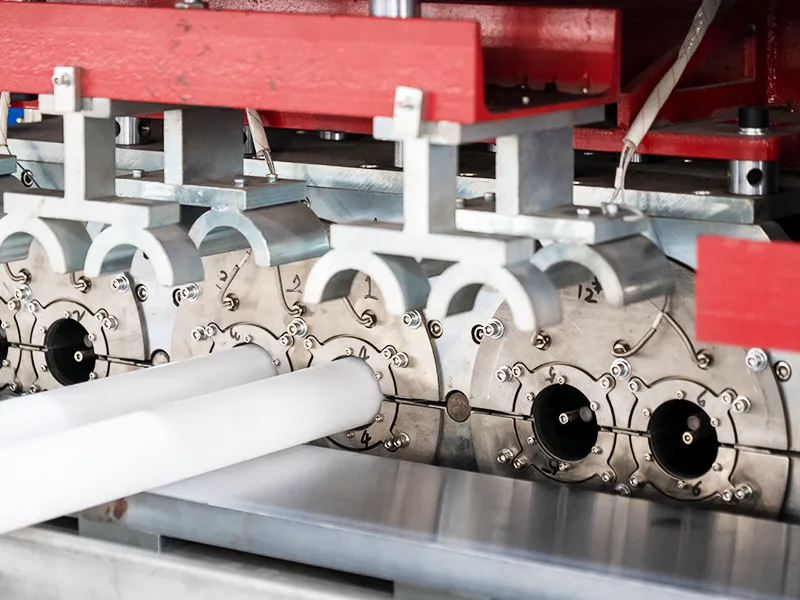

Plastic pipe belling is a critical stage in pipe production lines, creating socket ends that enable leak-proof joint connections. However, the belling process can be energy-intensive, particularly in high-volume operations.

For manufacturers competing in an increasingly cost-sensitive and environmentally conscious market, reducing energy consumption is not only a way to cut production costs but also a means to improve overall equipment efficiency and achieve sustainability targets.

Energy Consumption in Belling Machines

Plastic pipe belling involves heating, forming, and cooling pipe ends to create sockets. Each of these stages consumes energy differently:

- Heating Stage: Most energy is used here. Pipes are heated to the softening temperature (usually 120–140 °C for PVC) using either infrared (IR) heaters, hot air, or a combination.

- Forming Stage: A mechanical or vacuum forming system shapes the softened pipe end. Energy use is lower but depends on actuator types (hydraulic vs. pneumatic vs. servo).

- Cooling Stage: The shaped socket requires rapid cooling to maintain form. This stage uses compressed air or water spray, which consumes energy indirectly through pumps or compressors.

| Stage | Typical Energy Consumption Share | Key Energy Drivers |

| Heating | 50–70 % | Heater power rating, insulation, temperature control |

| Forming | 10–20 % | Actuation type, forming speed |

| Cooling | 20–30 % | Compressor efficiency, cooling water temperature, flow rate |

Table 1: Energy consumption distribution in typical belling processes

Major Energy Loss Points in Conventional Belling Lines

Despite improvements in machine design, many existing belling systems still waste energy unnecessarily, especially in older or manually controlled production lines. Common loss points include:

Inefficient Heating Systems

- Overpowered heaters run at constant full load even when not required.

- Lack of thermal insulation leads to heat loss to the environment.

- Poor temperature control causes overheating and longer heating times.

Prolonged Heating and Cooling Cycles

- Inconsistent temperature settings extend heating duration.

- Suboptimal cooling methods require extended compressor operation.

Inefficient Actuation Systems

- Pneumatic or hydraulic systems with continuous operation waste energy during idle times.

- Leakage in compressed air systems can increase energy use by 20–30 %.

Machine Standby and Idle Energy Waste

- Heaters and compressors often remain active during breaks or line downtime.

- Lack of smart standby modes leads to unnecessary power draw.

Poor Maintenance and Calibration

- Fouled heaters, aging seals, and worn-out actuators increase energy requirements.

- Non-calibrated sensors lead to inefficient control loops.

- Identifying these loss points is the first step toward implementing energy-saving measures that yield both immediate and long-term benefits.

Key Strategies to Reduce Energy Consumption

Energy-saving opportunities in plastic pipe belling processes can be grouped into five strategic categories:

Optimize Heating Efficiency

Since heating consumes the most energy, improving its efficiency can deliver substantial savings.

- Use Zoned Infrared Heating: Modern belling machines use multiple IR zones with independent control. This allows precise heating only where needed, reducing energy use by 15–25 %.

- Install High-Quality Thermal Insulation: Proper insulation around the heating chamber reduces radiant and convective heat loss.

- Adopt Smart Temperature Control: PID (Proportional–Integral–Derivative) controllers or PLC-based systems maintain target temperatures more precisely than manual control, minimizing overheating.

- Preheating Pipes Strategically: Utilizing residual heat from extrusion can reduce required belling heating energy, especially when machines are located close to the extruder.

Shorten Heating and Cooling Cycles

Time is energy. Faster heating and cooling cycles mean less energy per unit.

- Use Rapid IR Heaters: High-efficiency IR emitters can heat the pipe surface faster, allowing for shorter cycle times.

- Optimize Cooling Air Flow: Installing flow control valves or variable speed compressors reduces air flow when not needed.

- Closed-Loop Cooling Systems: Instead of continuously running compressors, closed-loop systems adjust airflow and temperature based on real-time socket temperature.

Upgrade Actuation Systems

Replacing or upgrading older actuation systems can yield both energy and productivity benefits.

- Switch from Pneumatic to Servo or Electric Actuators: Servo drives provide energy only when movement occurs, unlike pneumatic systems that consume compressed air continuously.

- Reduce Air Leaks: Regularly checking for and fixing leaks in pneumatic circuits can cut compressor energy by up to 30 %.

- Optimize Motion Profiles: Smooth acceleration and deceleration reduce peak loads and energy spikes.

Implement Intelligent Control and Automation

Intelligent automation reduces idle energy use and improves process consistency.

- Auto Standby Modes: Machines should automatically reduce heating power and compressor activity during downtime or product changeovers.

- Integrated PLC or SCADA Systems: Centralized control allows better synchronization between extrusion and belling, avoiding idle heating when pipes are not arriving.

- Energy Monitoring Sensors: Real-time monitoring highlights inefficient energy usage, allowing timely adjustments.

Maintenance and Preventive Actions

Well-maintained machines use less energy and last longer.

- Regular Heater Cleaning and Calibration: Dust and scale reduce IR heater efficiency over time.

- Check Insulation Integrity: Replace damaged or aged insulation promptly.

- Calibrate Sensors and Controllers: Accurate measurement leads to optimized energy use.

- Lubricate and Maintain Moving Parts: Reduces friction, improving actuator efficiency.

Energy-Efficient Technology Upgrades

Besides incremental improvements, manufacturers can consider technological upgrades that fundamentally improve energy performance.

| Technology | Energy Savings Potential | Investment Cost | Notes |

| Zoned IR Heating with PID Control | 15–25 % | Medium | Best ROI for older machines |

| High-Performance Thermal Insulation | 10–15 % | Low | Quick payback time |

| Servo Actuation | 20–30 % | High | Saves energy & improves precision |

| Variable Speed Compressor | 15–25 % | Medium | Reduces cooling energy |

| Real-Time Energy Monitoring | 5–10 % | Low | Enables continuous improvement |

Case Example:

A PVC pipe factory producing 200 m of pipe per hour installed zoned IR heaters with smart controllers. Belling energy fell 18%, cycle time improved 12%, achieving payback within 12 months.

Integration with the Entire Pipe Production Line

Belling is not an isolated process. Energy efficiency improves significantly when the belling machine is integrated with upstream and downstream equipment:

- Synchronization with Extrusion: By linking the extrusion line speed and temperature to the belling machine’s heating control, pipes can be belled while still warm, reducing heating energy demand.

- Buffer Conveyors: Continuous flow minimizes waiting time and idle heating.

- Centralized Cooling Systems: Shared, optimized cooling systems can serve multiple machines more efficiently than separate units.

Monitoring and Benchmarking Energy Performance

Energy savings cannot be managed without measurement. Manufacturers should adopt energy performance indicators (EnPIs) such as:

- kWh per Pipe Socket

- kWh per Meter of Pipe

- kWh per Production Hour

These KPIs should be tracked regularly and compared against targets or benchmarks. Installing energy meters on heater circuits, compressors, and actuators allows precise tracking.

Regular benchmarking against previous months or industry standards helps identify trends, justify investments, and maintain continuous improvement momentum.

Economic Benefits of Energy Reduction

Reducing energy consumption is not only about sustainability—it directly impacts the bottom line:

- Lower Electricity Bills: Even a 10–20 % reduction can yield significant annual savings in high-volume operations.

- Improved Equipment Lifespan: Lower thermal stress and optimized operation reduce wear on heaters and actuators.

- Higher Productivity: Faster cycles and reduced downtime increase output.

- Environmental Compliance: Many regions offer tax incentives or certifications for energy-efficient production.

For example, a mid-sized pipe manufacturer consuming 200,000 kWh annually for belling could save 40,000 kWh/year (≈ $4,000–$6,000) by implementing a mix of zoned heating, insulation, and air leak reduction measures.

Steps for Implementation

- Energy Audit: Assess current energy consumption per stage. Identify major losses.

- Set Targets: Define achievable reduction goals (e.g., 15 % in one year).

- Prioritize Actions: Start with low-cost, high-impact measures like insulation and leak repair.

- Upgrade Technology: Plan capital investments with ROI analysis.

- Train Operators: Proper operation and maintenance are key to sustaining savings.

- Monitor and Adjust: Use energy meters to track progress and fine-tune.

Conclusion

Reducing energy consumption in plastic pipe belling processes is both achievable and profitable. By understanding where energy is used and wasted, belling machine manufacturers can apply a combination of process optimization, technology upgrades, and maintenance practices to achieve significant savings.

Improving energy efficiency cuts costs, supports sustainability, and boosts overall production line performance. With well-planned investments and continuous monitoring, manufacturers can transform their belling operations into leaner, greener, and more competitive production units.