A belling machine (also called a socketing or end-forming machine) heats the end of a thermoplastic pipe—typically PVC, CPVC, PP, or PE—then reshapes it over a mandrel to create a socket (bell) that accepts another pipe’s spigot end. The bell may be smooth for solvent-cement joints or grooved to seat a rubber ring (elastomeric gasket).

Modern bell machines integrate heating, forming, calibration, cooling, and in-line inspection to deliver repeatable joints that meet dimensional standards, leak-tightness requirements, and ring retention requirements. Correctly specified and maintained, they improve field productivity, reduce coupler purchases, and ensure system integrity across water, sewer, drainage, electrical conduit, HVAC, and industrial process piping.

Why Pipe End Forming (Belling) Matters

- Faster installation: Socketed pipes push-fit or solvent-bond quickly, reducing on-site labor and weather exposure.

- Improved sealing: Bell geometry controls compression on gaskets or capillary action for solvent bonds.

- System integrity: Consistent dimensions reduce leaks, infiltration/exfiltration, and premature failures.

- Lower material cost: Integrated bells eliminate separate couplers on many lines.

- Standards compliance: Proper belling is essential to meet common dimensional and performance norms required by municipal and industrial buyers.

What a Belling Machine Does—Core Stations

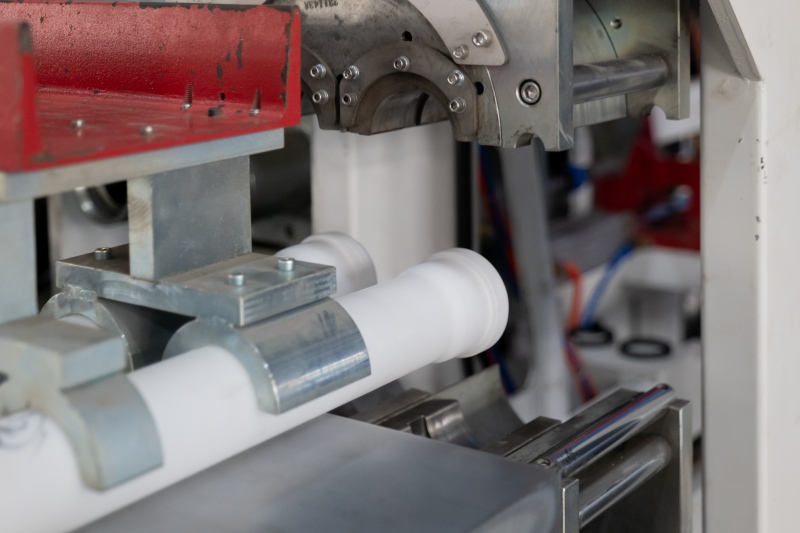

- Infeed & Clamping: The pipe length is indexed; clamps secure the OD without marring.

- Heating: Infrared, hot-air, hot-oil, or contact heating softens a controlled heat band at the pipe end.

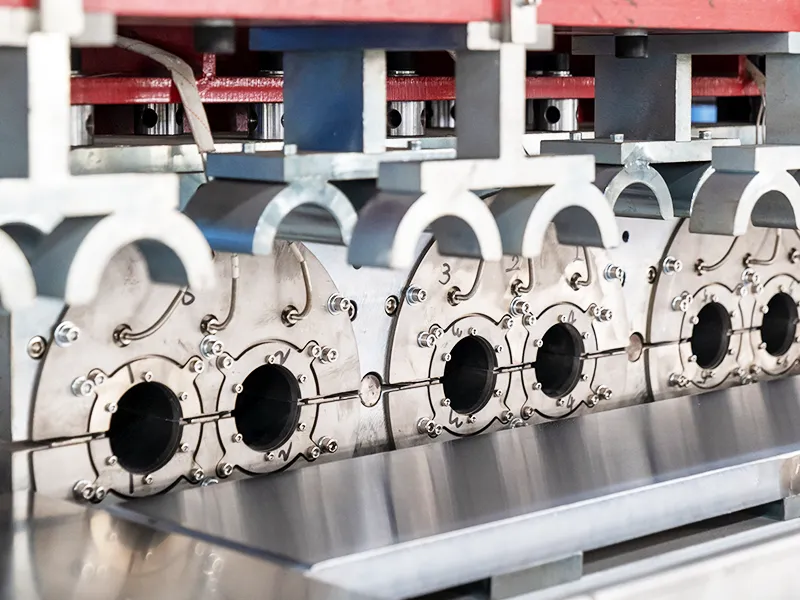

- Forming: A mandrel/core enters the softened end; vacuum and/or mechanical pressure expands the pipe end to the bell profile.

- Calibration & Groove Forming: The mandrel’s profile defines bell ID; inserts or rings machine the gasket groove if specified.

- Cooling: Air, mist, or water spray sets the geometry; controlled shrinkage locks in dimensions and ring retention.

- Ejection & Marking: The part exits; optional printers mark lot/date; vision checks bell depth, ovality, and groove position.

Typical Applications

- Water & wastewater: PVC/PP/PE gravity sewer, pressure water mains, drainage.

- Conduit & telecom: PVC conduit with solvent sockets, push-fit pulling.

- Chemical/industrial: CPVC/PP sockets in moderate-temperature service.

- HVAC & building: Condensate lines, ducted drains.

- Irrigation & agriculture: Quick field assembly and repair.

Pipe & Socket Types You’ll Encounter

Common Socket Profiles

- Solvent-cement socket (SC): Smooth bell with entry chamfer; capillary gap for adhesive.

- Elastomeric (RR): Bell with gasket groove; the elastomer compresses to seal under insertion/pressure.

- Double socket / coupler: Standalone belled sleeve (formed similarly) for repairs or joining cut lengths.

- Custom forms: Tapered bells, square-shoulder bells, special grooves for high-head or vacuum service.

Heating Technologies—What to Choose and Why

| Heating Method | Typical Materials | Pros | Cons | Typical Heat Band Length | Notes |

| Infrared (IR) | PVC, CPVC, PP | Fast response, clean, precise zoning | Reflectivity changes with color; needs shielding | 80–160 mm | Great for frequent size changes |

| Hot Air | PVC, PP, PE | Simple, low maintenance, uniform convective heat | Longer ramp; airflow can disturb light pipes | 100–200 mm | Good general-purpose choice |

| Hot Oil (Circulating) | CPVC, thick-wall PVC | Excellent uniformity & penetration | Slower changeovers, spill risk, higher maintenance | 120–220 mm | Favored for heavy-wall & CPVC |

| Contact/Plate | PVC | Efficient heat transfer, compact | Mark’s risk; tighter setup is needed | 60–120 mm | Used on small diameters & conduit |

Forming & Calibration—How the Socket Gets Its Shape

| Forming Method | How It Works | Best For | Advantages | Watch-outs |

| Mechanical Mandrel | Core pushes pipe to final shape | SC & RR | Simple, robust | Requires accurate heat window |

| Vacuum Assist | Vacuum ports draw pipe to mandrel | RR (groove fidelity) | Improves surface & groove accuracy | Needs clean manifold/filters |

| Collapsible Core | Core collapses for extraction | Deep bells, large sizes | Avoids dragging; protects groove | More complex mechanics |

| Servo-Controlled Positioning | Servo axes for mandrel travel & force | Tight tolerances | Repeatability, recipe control | Higher initial cost |

Material Behavior—Processing Windows & Dwell Times

| Material | Typical Softening Window (°C) | Typical Forming Dwell (s) | Cooling Dwell (s) | Notes |

| PVC (U-PVC) | 150–175 | 5–12 | 10–25 | Most common: pigment affects absorption |

| CPVC | 170–195 | 8–16 | 15–30 | Higher temp; careful thermal uniformity |

| PP-H / PP-B | 155–175 | 7–14 | 12–28 | Slower heat uptake; good recovery |

| PE (HDPE) | 140–165 | 6–12 | 12–24 | Memory (shrinkback) needs strong calibration |

Example Cycle Times & Throughput

Assumptions: Single-station belling head, automated infeed, standard RR socket with groove, water spray cooling, good ambient control.

| Pipe OD × Wall | Heat (s) | Form (s) | Cool (s) | Handling (s) | Cycle (s) | Parts/h |

| 63 mm × 3.0 mm | 9 | 5 | 12 | 4 | 30 | 120 |

| 110 mm × 4.2 mm | 12 | 6 | 16 | 5 | 39 | 92 |

| 160 mm × 6.2 mm | 16 | 7 | 20 | 6 | 49 | 73 |

| 250 mm × 9.6 mm | 22 | 9 | 26 | 7 | 64 | 56 |

| 400 mm × 12.3 mm | 32 | 12 | 38 | 8 | 90 | 40 |

Multi-station (2-up or 3-up) heads and tandem heaters can increase hourly throughput 1.6–2.5× depending on pipe length and handling automation.

Energy Use—Rule-of-Thumb Benchmarks

| Pipe OD | Heater Type | Avg Power During Heat (kW) | Cooling Water (L/min) | Compressed Air (NL/min) | kWh/1,000 Sockets (est.) |

| 63 mm | IR | 7 | 10 | 80 | 55–70 |

| 110 mm | Hot Air | 10 | 14 | 100 | 75–95 |

| 160 mm | Hot Air | 14 | 18 | 120 | 95–120 |

| 250 mm | Hot Oil | 20 | 24 | 140 | 130–170 |

| 400 mm | Hot Oil | 30 | 32 | 180 | 180–240 |

Dimensional Control & QC Checks (What to Measure)

- Bell ID at multiple planes (entry, groove base, socket stop)

- Bell depth & taper

- Groove position, width, and depth (for RR)

- Ovality (ID and OD)

- Surface finish & defects (scoring, orange-peel, chatter)

- Ring retention (force or dimensional surrogate)

- Leak & pressure tests (hydrostatic or vacuum as spec requires)

- Marking/traceability (date/shift/machine/recipe)

Typical Tolerances (illustrative)

- Bell ID: target ±0.20–0.40 mm (small OD) to ±0.60–0.80 mm (large OD)

- Groove width/depth: ±0.10–0.20 mm depending on ring design

- Ovality: ≤0.8% of diameter for most drainage; tighter for pressure systems

Common Defects & Troubleshooting

| Symptom | Likely Causes | Corrective Actions |

| Bell ovality | Uneven heating; misaligned clamps; mandrel off-center | Re-level clamps; re-center mandrel; balance heater zones |

| Groove shallow/deep | Wrong insert; thermal shrinkback; mis-timed vacuum | Verify insert spec; extend cool dwell; adjust vacuum timing |

| Wrinkles/buckling | Heat band too long; feed push too fast; wall too hot | Shorten heat zone; reduce feed rate; lower setpoint |

| Surface scuffing | Dry core; rough mandrel finish; extraction too hot | Improve mandrel polish; add release; increase cool |

| Poor ring retention | Groove geometry drift; under-cooling; resin memory | Re-calibrate; extend cooling; consider collapsible core |

| Solvent joint failures | Undersized ID; taper wrong; contamination | Check ID gauge; verify taper; improve housekeeping |

Changeover & Setup—A Practical Checklist

- Recipe load: OD, wall, socket type (SC/RR), heat setpoints, dwell times, servo profiles

- Mandrel & inserts: Correct profile, groove ring, stop position, entry chamfer

- Heater zoning: Verify active zones match heat band length; check element integrity

- Clamps & supports: Pads for current OD; no slippage; alignment pins seated

- Cooling: Flowrate & temperature; water filtration; mist nozzles clean

- Vacuum & air: Manifold filters clean; vacuum level stable; no leaks

- Metrology: ID plugs/rings, depth gauge, groove gauge ready and calibrated

- Trial pieces: Make 3–5 parts; measure; tweak; lock parameters and save version

Preventive Maintenance Plan (PM)

| Interval | Tasks |

| Daily | Clean mandrel; check clamps; inspect heaters for hot spots; drain water traps; verify coolant flow |

| Weekly | Lubricate linear guides; check vacuum filters; verify sensors (temp, position) |

| Monthly | Inspect heater elements; calibrate temperature controllers; polish mandrel if Ra worsens |

| Quarterly | Check servo backlash; verify alignment (mandrel to clamps); pressure test water circuit |

| Annually | Overhaul hot-oil loop (if used); replace wear pads; full metrology of bell gauges; controller firmware review |

Buying Guide—How to Specify a Belling Machine

- Pipe envelope: ODs, wall range, material (PVC/CPVC/PP/PE), lengths.

- Socket types: SC vs RR; groove geometry; bell depth; any special tapers.

- Throughput: Required parts/hour by OD; consider multi-station heads for large ODs.

- Heating strategy: IR for quick changeovers; hot oil for thick/CPVC; hot-air as generalist.

- Automation level: Infeed/outfeed conveyors; robot handling; inline leak/vision checks; printer.

- Recipe control: Servo axes, data logging, QR/ERP linkage, SPC dashboards.

- Utilities & footprint: kW, compressed air, cooling water (closed loop preferred), noise & fume extraction.

- Support: Local service, spare part lead times, training, remote diagnostics.

Mini-Case: Sizing for a Mixed-Diameter PVC Drainage Line

Objective: 25,000 sockets/week across 63–160 mm ODs, 5-day, 2-shift schedule (16 h/day).

Design picks: Hot-air heating, vacuum-assisted mandrel, 2-up head for ≤160 mm.

| Size Mix | Target Pcs/week | Chosen Cycle (s) | Stations | Realistic Pcs/h | Hours Needed |

| 63 mm | 10,000 | 22 | 2-up | 160 | 62.5 |

| 110 mm | 9,000 | 30 | 2-up | 120 | 75.0 |

| 160 mm | 6,000 | 42 | 2-up | 86 | 69.8 |

| Totals | 25,000 | — | — | — | 207.3 h |

Available hours: 16 h/day × 5 = 80 h/line.

Solution: Two identical lines (80 h × 2 = 160 h) plus 50 h overtime or third partial line; or upgrade to tandem heaters to cut heat time by ~20–25% and recover ~40 h.

A belling machine is the finishing engine of a thermoplastic pipeline—turning straight extrudates into field-ready, leak-tight components. The right combination of heating method, forming approach, cooling strategy, and automation yields stable geometry, fast cycles, and low scrap across materials and diameters. If you define your envelope (materials, sizes, socket types) and insist on robust recipe control and metrology, you’ll achieve faster installations, improved sealing, and lower lifetime cost for your pipeline customers.