Good quality Tube Socket Belling Machine - DS1000 Belling machine – Yuyu Detail:

| Pipestandards

|

Model | DS1000 |

| standard | U-PVC pipes | |

| Diameter | 630mm – 1000mm | |

| Pipe Length | 6m | |

| Heating | Heating way | 1 oven (Option: 2 ovens)Stainless steel body, long service life |

| Pipe Rotary | Clockwise and anti-clockwise | |

| Electrical | PLC and Screen | Siemens |

| low-voltage apparatus | Schneider, Omron | |

| Total Power | 73KW | |

| Pneumatic | Compressed air pressure | 0.6Mpa |

| Water | Water pressure | 0.4Mpa |

| Hydraulic | Hydraulic pressure | 8.0Mpa |

| Equipmentappearance

|

Machine type | Automatic, single line, one pipes per cycle |

| Machine dimension | 10000mm(L)×4600mm(W)×2570mm(H) | |

| Machine weight | 15000kg | |

| Operating principle

|

U-type | Pushing the mould into pipe directly |

| R-type | With ext - pressure and collapsible mandrel | |

| Cooling type | Water – cooling | |

| Machine speed | Max. 900S/pipe |

| No. | Items | YUYU* Desheng |

| 1. | Company scale | Covers an area of 53,000 sq.m. with more than 20 years’ experience for machinery. With over 100 staff group. |

| 2. | Certification | CE; ISO; high-tech enterprise; with patents |

| 3. | Electrical components | Siemens, Mitsubishi, Schneider, Omron, Autonics, etc Taiwan Ashun, Yinchuan Changcheng, Or Taiwan Ashun |

| 4. | R-type working way | 2 ways: suitable for thin and thick wall thickness pipes.No.1 segment in first, after heating, pipe insert on the moulds, segment out, increase ext- pressure to take sharp.No.2 segment out first, after heating, pipe insert on the moulds, increase ext-pressure to take sharp. |

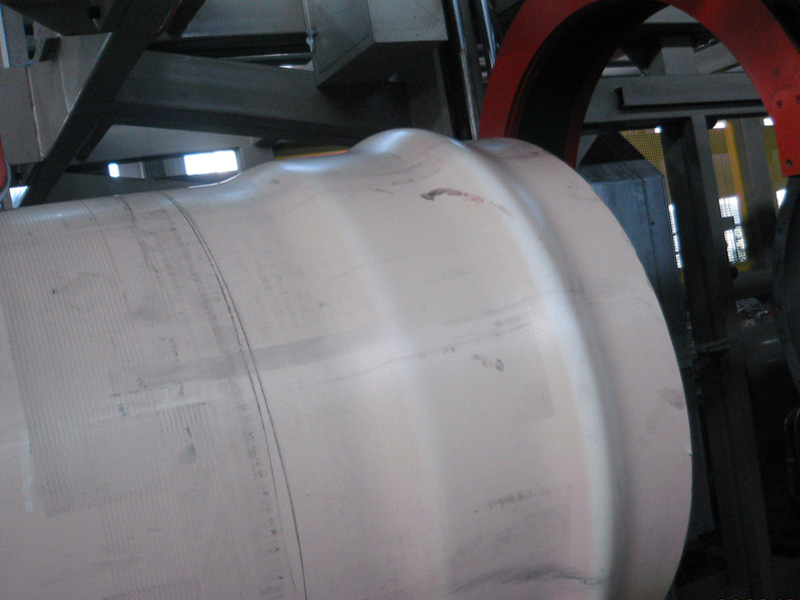

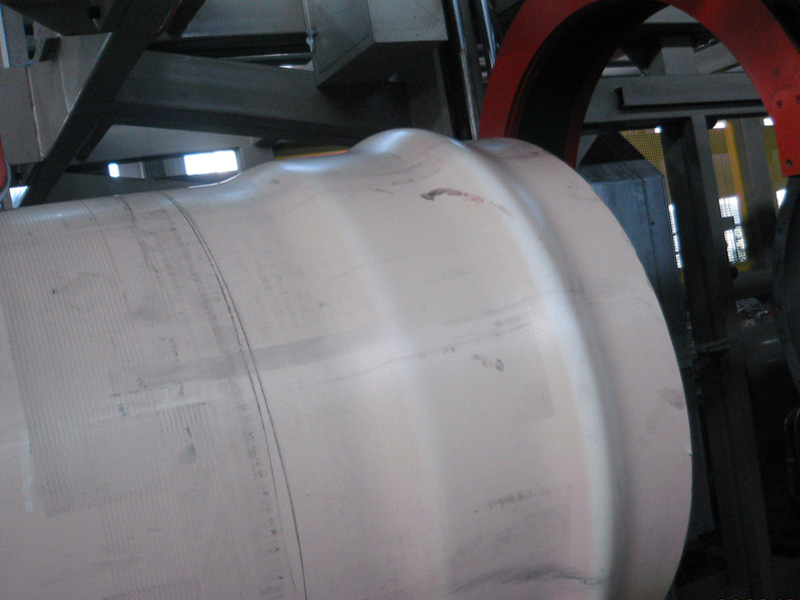

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Good quality Tube Socket Belling Machine - DS1000 Belling machine – Yuyu, The product will supply to all over the world, such as: Bangladesh , Durban , Ethiopia , We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we have better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We are always here working for your demands whenever you need.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

-

Hot sale Factory Powerful Portable Chamfering M...

-

Original Factory Chamfering Machine For Tube - ...

-

Massive Selection for 630mm Pvc Belling Machine...

-

Hot sale Plastic Cable Tray Slotting Machine - ...

-

Chinese wholesale Cnc Bending Machine Price - ...

-

High Quality Hydro Tester Machine - RBM250-AS ...